Advanced Filters

Category

Subcategory

Manufacturer

Condition

Delta/ Invicta 8'' Long Bed Jointer w/ New Byrd Head

Price:

$2,995 (USD)

Delta/ Invicta 8'' Long Bed Jointer

Complete with a new byrd head & bearing

Key Lock Out

115/ ...

USED QUICKWOOD PRO 1100 ELITE SANDER

Price:

$39,995 (USD)

The Quickwood PRO 1100 Elite Sander, now available in a used condition, offers dependable perform...

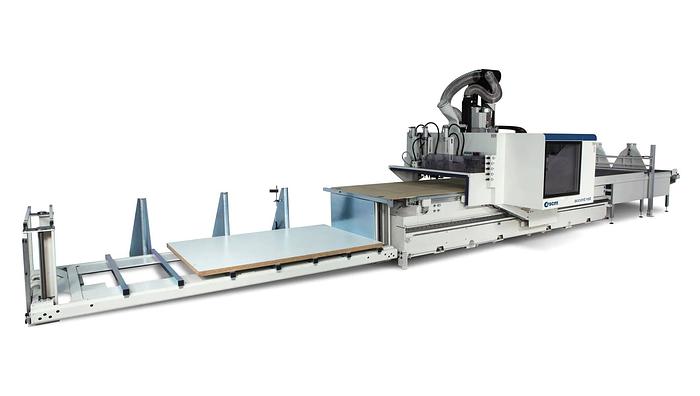

SCM n 100 CR Plus CNC Router

Price:

The SCM n 100 CR Plus CNC Router is a reliable used equipment option for woodworking or related i...

SCM- olympic 300ert Single-Sided Automatic Edgebander

Price:

$71,000 (USD)

Compact edge bander with a sturdy framework that guarantees reliability and repeatability.

Thank...

SCM- olympic 300b Single-Sided Automatic Edgebander

Price:

$43,000 (USD)

Compact edge bander with a sturdy framework that guarantees reliability and repeatability.

Thank...

SCM- olympic 300te Single-Sided Automatic Edgebander

Price:

$53,000 (USD)

Compact edge bander with a sturdy framework that guarantees reliability and repeatability.

Thank...

Doucet Drawer Clamp Model #DWM36

Price:

$6,500 (USD)

Showroom Machine

The Doucet Drawer Clamp Model #DWM36 is a robust and reliable piece of machiner...

Steff Power Feeder; Model #:VarioSteff 3 (1PH)

Price:

$1,895 (USD)

(3) rollers, variable speed from 9 to 59 FPM 1 HP motor 4-3/4" roller diameter 2-1/4" roller widt...

Steff Power Feeder; Model #: 2048 (3PH)

Price:

$1,595 (USD)

4) Rollers and (8) speeds of 6-13-18-21-36-42-54-102 FPM 0.7/1 HP motor 4-3/4" roller diameter 2-...

Steff Power Feeder; Model #: 2068 (3PH)

Price:

$2,475 (USD)

(6) Rollers and (8) speeds of 6-13-16-21-36-42-54-102 FPM 0.7/1 HP motor 4-3/4" roller diameter 2...

Steff Power Feeder; Model #: 2032 Hobby Class

Price:

$795 (USD)

(3) Rollers and (4) speeds 0.25 HP motor Stand included 1-phase, 115v OR 230V Weight: 78 lbs. | Shipping: $1...

Steff Power Feeder; Model #:VarioSteff 4 (3PH)

Price:

$1,925 (USD)

(4) rollers, variable speed from 9 to 59 FPM 1 HP motor; 4-3/4" roller diameter 2-1/4" roller wid...

Steff Power Feeder; Model #: 2048 (1PH)

Price:

$1,695 (USD)

4) Rollers and (8) speeds of 6-13-18-21-36-42-54-102 FPM 0.7/1 HP motor 4-3/4" roller diameter 2-...

Steff Power Feeder; Model #:VarioSteff 4 (1PH)

Price:

$2,025 (USD)

(4) rollers, variable speed from 9 to 59 FPM 1 HP motor; 4-3/4" roller diameter 2-1/4" roller wid...

SteffSteff Power Feeder; Model #: 2044 (3PH)

Price:

$1,375 (USD)

(4) Rollers and (4) speeds of 13-26-36-72 FPM 0.7/1 HP motor 4-3/4" roller diameter 2-1/4" roller...

Steff Power Feeder; Model #: 2038CL (1PH)

Price:

$1,750 (USD)

Belted feeder with (3) belts and (8) speeds of 6-13-16-21-36-42-54-102 FPM 1 HP motor Complete wi...

Steff Power Feeder; Model #: 2038 Roller Speed 8

Price:

$1,375 (USD)

(3) Rollers and (8) speeds of 6-13-18-21-36-42-54-102 FPM 1 HP motor 4-3/4" roller diameter; 2-1/...

Steff Power Feeder; Model #: 2044 (1PH)

Price:

$1,475 (USD)

(4) Rollers and (4) speeds of 13-26-36-72 FPM 0.7/1 HP motor 4-3/4" roller diameter 2-1/4" roller...

Steff Power Feeder; Model #: 2034 (3PH)

Price:

$1,195 (USD)

(3) Rollers and (8) speeds of 6-13-18-21-36-42-54-102 FPM 1 HP motor 4-3/4" roller diameter 2-1/4...

Steff Power Feeder; Model #: 2038 (1PH)

Price:

$1,475 (USD)

(3) Rollers and (8) speeds of 6-13-18-21-36-42-54-102 FPM 1 HP motor 4-3/4" roller diameter 2-1/4...

Steff Power Feeder; Model #: 2038 (3PH)

Price:

$1,375 (USD)

(3) Rollers and (8) speeds of 6-13-18-21-36-42-54-102 FPM 1 HP motor 4-3/4" roller diameter 2-1/4...

Steff Supersonic 4 Power Feeder

Price:

$2,150 (USD)

(4) Rollers Variable speed up to 82 feet per minute (108.5 FPM with optional gears) Quick forward...

Steff Power Feeder; Model #: 2034 (1PH)

Price:

$1,295 (USD)

(3) Rollers and (4) speeds of 13-26-36-72 FPM 1 HP motor 4-3/4" roller diameter 2-1/4" roller wid...

Steff Supersonic 3 Power Feeder

Price:

$1,995 (USD)

(3) Rollers Variable speed up to 82 feet per minute (108.5 FPM with optional gears) Quick forward...

MAGGI BEST 960CE Radial Arm Saw

Price:

$7,650 (USD)

Maggi radial arm saws offer adaptability, versatility, precision and durability to shops of all s...

MAGGI Big 800CE Radial Arm Saw

Price:

$6,550 (USD)

Maggi radial arm saws offer adaptability, versatility, precision and durability to shops of all s...

MAGGI Junior 640CE Radial Arm Saw

Price:

$5,850 (USD)

Maggi radial arm saws offer adaptability, versatility, precision and durability to shops of all s...

MAGGI System 21 Prestige Construction/Line Borer

Price:

$7,650 (USD)

The Maggi System 21 Prestige Boring Machine provides a 21 spindle 32 mm universal drilling soluti...

SCM SI 315ES Sliding Table Saw

Price:

$12,775 (USD)

Circular saw with tilting blade with professional performances for a quality without compromises....

SCM TW 55ES Tilting Shaper- 3PH

Price:

$11,675 (USD)

The right spindle moulder for demanding craftsmen and carpentries, thanks to its customization an...

SCM TW 55ES Tilting Shaper- 1PH

Price:

$12,275 (USD)

The right spindle moulder for demanding craftsmen and carpentries, thanks to its customization an...

SCM Class TI 120 Tilting Shaper

Price:

$17,575 (USD)

The best solution for every application.

Precision and reliability with the the technological de...

SCM STR 32R Brushing Machine

Price:

$16,975 (USD)

The standard formula rustication units/brushing machines are the ideal solution for rustication p...

SCM STR 32L Brushing Machine

Price:

$19,975 (USD)

The standard formula rustication units/brushing machines are the ideal solution for rustication p...

SCM ME 28ET Edgebander- 1PH

Price:

$21,475 (USD)

Automatic edge bander with glue pot and pre-milling unit to edge band, with great flexibility, wi...

SCM STR 62R

Price:

$21,975 (USD)

The standard formula rustication units/brushing machines are the ideal solution for rustication p...

SCM STR 62L

Price:

$24,975 (USD)

The standard formula rustication units/brushing machines are the ideal solution for rustication p...

SCM CLASS M 3 Multi-Blade Gang Rip Saw

Price:

$62,475 (USD)

Compactness and simplicity of construction for a high performance multiblade.

Advantages

Anti-k...

SCM Group TW 45C Fixed Spindle Shaper

Price:

$6,475 (USD)

The spindle moulder, with sliding table and fixed spindle, versatile and easy to use, ideal for D...

SCM Group CLASS TF 130PS Fixed Spindle Shaper

Price:

$16,975 (USD)

The "flexible" par excellence. Designed to manage tenoning and moulding operations very easily. A...

SCM Group CLASS TF 130 Fixed Spindle Shaper

Price:

$14,475 (USD)

The best solution for every application. Essential and professional the manual version. Technolog...

SCM Group NOVA TF 110 Fixed Spindle Shaper

Price:

$10,975 (USD)

Guaranteed quality at your finger tips. Easy-to-use, productivity and efficency, flexibility. Adv...

SCM Group Class SI X 3-Phase 10.5’ Programmable Sliding Table Saw

Price:

$56,975 (USD)

The advantages of an exclusive choice. Advantages Double blade tilting: maximum height without co...

SCM Group Class SI 350 - 3 Phase 10.5’ Sliding Table Saw

Price:

$21,475 (USD)

High construction quality for reliability and safe performance. Advantages Saw unit: a perfect cu...

SCM Group Nova SI 400 - 3 Phase 10.5’ Programable Sliding Table Saw

Price:

$15,475 (USD)

Programmed or manual circular saws with 400 mm blade. Guaranteed quality at your finger tips. Adv...

SCM Group Class SI 400EP- BO- 3 Phase 10.5’ Programable Sliding Table Saw

Price:

$73,475 (USD)

Superior technology combined with an ease of use. Advantages Saw unit: a perfect cut. Maximum tor...

SCM Group Class SI 400 EP - 3 Phase 10.5’ Sliding Table Saw

Price:

$36,975 (USD)

Superior technology combined with an ease of use. Main functions: Connectivity among machines bel...

SCM Group Nova SI 400EP - 3 Phase 10.5’ Programable Sliding Table Saw

Price:

$26,775 (USD)

Superior technology combined with an ease of use. Advantages Saw unit: a perfect cut. Maximum tor...

SCM Group NOVA SI 300S- 3Ph 5.5’ Manual Short Stroke Sliding Table Saw

Price:

$14,475 (USD)

Guaranteed quality at your fingertips Essential configuration with complete equipment to carry ou...

MiniMax SC4E 8.5' - 1ph Manual Sliding Table Saw

Price:

$10,475 (USD)

Circular saw with tilting blade for demanding craftsmen and carpentries which combines working ac...

SCM T 20

Price:

$9,975 (USD)

Trimming of shaped panels and with tilted edge.

Simply intelligent and versatile. Designed with ...

SCM Me 25- 3 PH

Price:

$17,775 (USD)

Automatic edge bander with glue pot to edge band, with great flexibility, with melaminic edges, P...

SCM E 20

Price:

$10,975 (USD)

Edge banding with hot melt glueon edges in rolls and strips on shaped panels, simply essential an...

SCM Me 20

Price:

$11,775 (USD)

Technological solution, for professional craftsmen and joineries, to edge band with an amazing ea...

MiniMax SC3 Classic 5.5' - 1ph Manual Sliding Table Saw

Price:

$9,575 (USD)

The compact and highly precise circular saw with a low investment for DIY woodworkers and craftsm...

SCM MiniMax SC2 Classic 5.5' - 1ph Manual Sliding Table Saw

Price:

$6,475 (USD)

The precise, cost-effective and compact circular saw with tilting blade for the D.I.Y. woodworker...

MiniMax fs41 Classic 16" Jointer/Planer w/ Tersa Head (1 ph)

Price:

$7,375 (USD)

The surfacing-thicknessing planer powerful and user friendly, for D.I.Y. woodworkers and craftsme...

SCM Minimax fs 30c x Jointer/Planer w/ Xylent Head

Price:

$6,375 (USD)

Massive, high-precision, professional band saws for serious woodworkers and production shops. The...

SCM Minimax fs 30c Jointer/Planer w/ Tersa Head

Price:

$5,775 (USD)

The surfacing-thicknessing machine for the D.I.Y. woodworkers and the craftsmen joineries. Fine W...

SCM Group Programmable Planer with Xylent Head L'Invincibile S7 X

Price:

$28,475 (USD)

SCM Group Programmable Planer with Xylent Head L'Invincibile S7 X Description Programmable Planer...

SCM Group Class S630 Planer w/ Xylent

Price:

$25,475 (USD)

The best solution for every application. Easy and precise, practical design, a wider range of app...

SCM Group Class S630 Planer w/ Tersa

Price:

$23,975 (USD)

The best solution for every application. Easy and precise, practical design, a wider range of app...

SCM Group Nova S520 Planer w/ Xylent

Price:

$15,575 (USD)

Guaranteed quality at your finger tips. Easy and precise, practical design, a wider range of appl...

SCM Group Nova S520 Planer w/Tersa

Price:

$14,975 (USD)

Guaranteed quality at your finger tips. Easy and precise, practical design, a wider range of appl...

SCM Group 20" L'Invincibile Long Bed Jointer with Xylent Head F7 X

Price:

$22,775 (USD)

SCM Group 20" L'Invincibile Long Bed Jointer with Xylent Head F7 X Description Programmable 20” l...

SCM Group Nova F520 Jointer w/ Xylent

Price:

$14,475 (USD)

Guaranteed quality at your finger tips. Perfect surfaces, practical and safe, ergonomics. Advanta...

SCM Group Nova F520 Jointer w/ Tersa

Price:

$13,875 (USD)

Guaranteed quality at your finger tips. Perfect surfaces, practical and safe, ergonomics. Advanta...

SCM Group Nova F410 Jointer w/ Xylent

Price:

$12,675 (USD)

Guaranteed quality at your finger tips. Perfect surfaces, practical and safe, ergonomics. Advanta...

SCM Group Nova F410 Jointer w/ Tersa

Price:

$11,975 (USD)

Guaranteed quality at your finger tips. Perfect surfaces, practical and safe, ergonomics. Advanta...

MiniMax S640P- 3 Phase Bandsaw

Price:

$9,975 (USD)

PROFESSIONAL SERIES Massive, high-precision, professional band saws for serious woodworkers and p...

MiniMax S640P- 1 Phase Bandsaw

Price:

$9,475 (USD)

PROFESSIONAL SERIES Massive, high-precision, professional band saws for serious woodworkers and p...

MiniMax S540P- Single Phase Bandsaw

Price:

$7,475 (USD)

PROFESSIONAL SERIES Massive, high-precision, professional band saws for serious woodworkers and p...

SCM MiniMax S440P- Single Phase Bandsaw

Price:

$5,775 (USD)

PROFESSIONAL SERIES Massive, high-precision, professional band saws for serious woodworkers and p...

SCM Minimax s 45n Bandsaw

Price:

$3,975 (USD)

The minimax s 45n is an SCM Group made 2.5hp motor bandsaw. With over 20 years of service to the ...

MiniMax lab300p 5.5' Combination Machine w/ 12'' Tersa Head

Price:

$10,475 (USD)

Universal combined machine with all minimax quality, at the most affordable price, ideal for dema...

MiniMax CU 300C 5.5' Combination Machine w/ 12'' Tersa Head

Price:

$13,775 (USD)

Universal combined machine with all minimax quality, at the most affordable price, ideal for dema...

MiniMax CU 410E 8.5' Combination Machine w/ 16'' Tersa Head

Price:

$20,975 (USD)

Universal combined machine with all minimax quality, at the most affordable price, ideal for dema...

MiniMax CU 410ES 10.5' Combination Machine w/14'' Main Blade, 16'' Tersa Head

Price:

$28,975 (USD)

Universal combined machine with all minimax quality, at the most affordable price, ideal for dema...

SCM Startech CN Plus

Price:

$69,975 (USD)

startech cn plus has been designed for the small-medium woodworking workshops but also for larger...

SCM Startech CN V

Price:

$41,975 (USD)

startech cn v is the new CNC drilling machine with fixed work table and mobile workpiece. Vertica...

SCM Startech CN K Compact CNC Machine

Price:

$12,975 (USD)

(the machine stand in the picture is optional) Compact 3-axis machining centre ideal for all type...

MiniMax Startech 27- 3 Phase 27 Hole In-Line Boring Machine

Price:

$10,975 (USD)

Ideal for boring operations on panel. New models with 27 and 21 spindles. Rich basic equipment: i...

Minimax T124 Wood Turning Lathe Sander

Price:

$6,475 (USD)

Strong base ensures maximum reliability and top precision turning. Copier ideal for small batches...

MiniMax LS-2500 Sander -3PH

Price:

$9,475 (USD)

Belt sander with double gooseneck for craftsmen and professional workshops. Advantages Excellent ...

Cantek 8′ Sliding Table Saw D405M-8 (3PH)

Price:

$13,200 (USD)

CANTEK | D405M-8 8′ SLIDING TABLE SAW Industrial manually operated sliding table saw for the spac...

Cantek 10′ Sliding Table Saw D405M-10 (1PH)

Price:

$13,900 (USD)

CANTEK | D405M-10 10′ SLIDING TABLE SAW Industrial manually operated sliding table saw. The Cante...

Cantek 10′ Sliding Table Saw D405M-10 (3PH)

Price:

$13,900 (USD)

CANTEK | D405M-10 10′ SLIDING TABLE SAW Industrial manually operated sliding table saw. The Cante...

Cantek Lineal Brust Sander LBS300-5S

Price:

$18,700 (USD)

CANTEK | LBS300-5S 3-SIDED LINEAL BRUSH SANDER Eliminate hand sanding with our economical sanding...

Cantek Oscillating Edge Sander OES512D

Price:

$12,100 (USD)

CANTEK | OES512D HEAVY DUTY OSCILLATING EDGE SANDER Industrial oscillating edge sander for the mo...

Cantek 8′ Sliding Table Saw D405M-8 (1PH)

Price:

$13,300 (USD)

CANTEK | D405M-8 8′ SLIDING TABLE SAW Industrial manually operated sliding table saw for the spac...

Cantek Oscillating Edge SanderOES509D

Price:

$10,500 (USD)

CANTEK | OES509D HEAVY DUTY OSCILLATING EDGE SANDER Industrial oscillating edge sander for the mo...

CANTEK | S432 43″ TWO HEAD WIDEBELT SANDER

Price:

$32,600 (USD)

Accomplish your tasks without worrying about the performance of your sander. The Cantek S432 43″ ...

CANTEK | S431 43″ WIDEBELT SANDER

Price:

$27,900 (USD)

Dependable, consistent sanding results at an affordable price. The Cantek S431 43″ Widebelt Sande...

Cantek 36″ Two Head Widebelt Sander (60" Belt) S372 (3PH)

Price:

$26,100 (USD)

CANTEK | S371 36″ WIDEBELT SANDER Dependable, consistent sanding results with a robust design tha...

Cantek 36″ Widebelt Sander (60" Belt) S371 (1PH)

Price:

$19,900 (USD)

CANTEK | S371 36″ WIDEBELT SANDER Dependable, consistent sanding results with a robust design tha...

Cantek 36″ Widebelt Sander (60" Belt) S371 (3PH)

Price:

$19,900 (USD)

CANTEK | S371 36″ WIDEBELT SANDER Dependable, consistent sanding results with a robust design tha...

Cantek 24″ Widebelt Sander (60" Belt) S251 (1PH)

Price:

$14,600 (USD)

CANTEK | S251 24″ WIDEBELT SANDER A robust widebelt sander with minimal footprint. The Cantek S25...

Cantek 24″ Widebelt Sander (60" Belt) S251 (3PH)

Price:

$14,200 (USD)

CANTEK | S251 24″ WIDEBELT SANDER A robust widebelt sander with minimal footprint. The Cantek S25...

Cantek 44'' Widebelt Sander (60'' Belt) C431 (3 PH)

Price:

$27,600 (USD)

** Also available in 1PH- ask for pricing ** Also available Cantek 43'' Two Head Widebelt Sander ...

Cantek 36'' Two Head Widebelt Sander (60'' Belt) C372 (3PH)

Price:

$30,500 (USD)

CANTEK | C372 37″ TWO HEAD WIDEBELT SANDER Accomplish your tasks without worrying about the perfo...

Cantek 36'' Widebelt Sander (60'' Belt) C371 (1PH)

Price:

$21,900 (USD)

CANTEK | C371 36″ WIDEBELT SANDER Dependable, consistent sanding results with a robust design tha...

Cantek 36'' Widebelt Sander (60'' Belt) C371 (3PH)

Price:

$21,000 (USD)

CANTEK | C371 36″ WIDEBELT SANDER Dependable, consistent sanding results with a robust design tha...

Cantek 24'' Widebelt Sander (60'' Belt) C251 (1PH)

Price:

$13,100 (USD)

A robust widebelt sander with minimal footprint. The Cantek C251 24″ Widebelt Sander is compact a...

Cantek 24'' Widebelt Sander (60'' Belt) C251 (3PH)

Price:

$12,300 (USD)

Also available in 1PH...... $13,100 A robust widebelt sander with minimal footprint. The Cantek C...

Cantek 7.5 HP Spindle Shaper w/ Tilting Shaper SS512TB

Price:

$12,600 (USD)

CANTEK | SS512TB TILTING SHAPER Production 7.5 HP tilting spindle shaper. The Cantek SS512TB tilt...

Cantek CFS 100 Automatic Defect Cutoff Chop Saw

Price:

$61,600 (USD)

CANTEK | CFS100 AUTOMATIC DEFECT CUTOFF CHOP SAW

An economical and high-speed approach to defect...

Cantek PCM610 24'' Miter Cutting Chop Saw

Price:

$29,900 (USD)

CANTEK | PCM610 24″ MITER CUT-OFF SAW Large capacity miter cut-off saw is built for production. T...

Cantek PCM508 20'' Miter Cutting Chop Saw

Price:

$19,000 (USD)

CANTEK | PCM508 20″ MITER CUT-OFF SAW Large capacity miter cut-off saw is built for production. T...

Cantek PCS36 36'' Pneumatic Chop Saw w/ Foot Pedal Control (LH or RH)

Price:

$28,500 (USD)

CANTEK | PCS36 36″ PNEUMATIC CUT-OFF SAW Large capacity crosscutting solution. The Cantek PCS36 3...

Cantek PCS30 30'' Pneumatic Chop Saw w/ Foot Pedal Control (LH or RH)

Price:

$20,000 (USD)

CANTEK | PCS30 30″ PNEUMATIC CUT-OFF SAW Large capacity crosscutting solution. The Cantek PCS30 3...

Cantek PCS24 24'' Pneumatic Chop Saw w/ Foot Pedal Control (LH or RH)

Price:

$14,700 (USD)

Large capacity crosscutting solution. The Cantek PCS24 24” pneumatic chop saw is the ideal soluti...

Cantek PCS18M 18'' Non-Ferrous Pneumatic Chop Saw w/ Foot Pedal (LH or RH)

Price:

$10,400 (USD)

PCS18MD 18'' Non-Ferrous Pneumatic Chop Saw w/ Dual Push Button Control (LH or RH) .........add $...

Cantek PCS18 18'' Pneumatic Chop Saw w/ Foot Pedal Control (LH or RH)

Price:

$7,800 (USD)

PCS18D 18'' Pneumatic Chop Saw w/ Dual Push Button Control (LH or RH) .........add $560 Or 460 V ...

Cantek PCS14 14'' Pneumatic Chop Saw w/ Foot Pedal Control (LH or RH)

Price:

$7,100 (USD)

PCS14D 14'' Pneumatic Chop Saw w/ Dual Push Button Control (LH or RH) ........ add $530 Or 460V …...

Cantek D405 ANC 1 Axis Sliding Table Saw

Price:

$18,100 (USD)

Stop walking around your saw with the programmable rip fence. The Cantek D405ANC 1-Axis Sliding T...

Cantek P305 10′ Sliding Table Saw (3PH)

Price:

$10,700 (USD)

Powerful features in a small footprint sliding panel saw. The Cantek P305 10’ Sliding Table Saw i...

Cantek P305 10′ Sliding Table Saw (1PH)

Price:

$11,000 (USD)

Powerful features in a small footprint sliding panel saw. The Cantek P305 10’ Sliding Table Saw i...

Cantek P30 5′ Sliding Table Saw (1PH/3PH)

Price:

$9,300 (USD)

Powerful features in a small footprint sliding panel saw. The Cantek P30 5′ Sliding Table Saw is ...

Cantek Oscillating Edge Sander Model PW120E

Price:

$8,200 (USD)

Versatile edge sander for doors, drawer boxes and more. The Cantek PW120E Oscillating Edge Sander...

Cantek Manual Oscillating Edge Brush Sander E6

Price:

$5,100 (USD)

CANTEK | E6 OSCILLATING EDGE BRUSH SANDER Oscillating brush sander for sanding the edges of cabin...

Cantek Pneumatic Overarm Pin Router SR750

Price:

$14,400 (USD)

CANTEK | SR750 PNEUMATIC OVERARM PIN ROUTER There is nothing like an Overarm Router for productio...

Cantek Multi Blade Gang Ripsaw MRS300

Price:

$39,700 (USD)

CANTEK | MRS300 MULTI BLADE GANG RIPSAW A powerful multi ripsaw for the most demanding ripping ap...

CANTEK R18 BOTTOM CUTTING STRAIGHT LINE RIPSAW

Price:

$31,200 (USD)

CANTEK | R18 BOTTOM CUTTING STRAIGHT LINE RIPSAW

A precision straight line ripsaw for high produ...

CANTEK R16 BOTTOM CUTTING STRAIGHT LINE RIPSAW

Price:

$26,200 (USD)

CANTEK | R16 BOTTOM CUTTING STRAIGHT LINE RIPSAW

A precision straight line ripsaw for high produ...

Cantek 14'' Glue Line Rip Saw C14RS

Price:

$30,800 (USD)

Large capacity glue line ripsaw with precision straight line results. The Cantek C14RS Straight L...

Cantek 13'' Glue Line Rip Saw SRS330 (230V/ 460V)

Price:

$24,700 (USD)

Precision glue joint ripsaw built for power and speed. The Cantek SRS330 Straight Line Glue Joint...

Cantek 12'' Glue Line Rip Saw C12RSH

Price:

$21,700 (USD)

Save time and speed up production in your ripping operations. The Cantek C12RSH Straight Line Glu...

Cantek 10'' Straight Line Rip Saw 303S

Price:

$15,000 (USD)

Save time and speed up production in your ripping operations. The Cantek 303S single blade ripsaw...

Cantek 30'' X 8'' Double Surface Planer GT760ARD-8

Price:

$47,200 (USD)

Plane your material efficiently in a single pass. The Cantek GT760ARD 30″ Double Surface Planer h...

Cantek 25'' X 8'' Double Surface Planer GT635ARD-8

Price:

$40,300 (USD)

CANTEK | GT635ARD 25″ DOUBLE SURFACE PLANER Plane your material efficiently in a single pass. The...

Cantek 16'' X 6.7'' Double Surface Planer GT400BRD

Price:

$28,600 (USD)

CANTEK | GT400BRD 16″ DOUBLE SURFACE PLANER Plane your material efficiently in a single pass. The...

Cantek 4-Sided Planer Moulder M412 (3PH)

Price:

$24,600 (USD)

CANTEK | M412 4-SIDED PLANER MOULDER Economical 4-Sided Planer Moulder Solution for the Small Sho...

Cantek 26″ Planer CM626 (3PH)

Price:

$25,500 (USD)

CANTEK | CM626 26″ PLANER Powerful 26” heavy duty planer that fits your everyday needs. The Cante...

Cantek 32″ Planer P815HV (3PH)

Price:

$31,700 (USD)

CANTEK | P815HV 32″ PLANER Powerful heavy duty 32” planer that fits your everyday needs. The Cant...

Cantek 24″ Planer P630HV (3PH)

Price:

$18,000 (USD)

Powerful heavy duty 24” planer that fits your everyday needs. The Cantek P630HV 24″ Planer has a ...

Cantek 20″ Planer P508HV (3PH)

Price:

$15,100 (USD)

Powerful heavy duty 20” planer that fits your everyday needs. The Cantek P508HV 20” Planer has a ...

Cantek 24″ Planer P24HV (3PH)

Price:

$12,300 (USD)

Compact and economically priced 24” planer with spiral cutterhead. The Cantek P24HV 24” Planer ha...

Cantek 20″ Planer P20HV (3PH)

Price:

$8,700 (USD)

Compact and economically priced 20” planer with spiral cutterhead. The Cantek P20HV 20” Planer ha...

Cantek 20″ Planer P20HV(1PH)

Price:

$9,600 (USD)

Compact and economically priced 20” planer with spiral cutterhead. The Cantek P20HV 20” Planer ha...

Cantek J168LH 16'' Jointer w/ Spiral Cutterhead (3PH)

Price:

$12,900 (USD)

CANTEK | J168LH HEAVY DUTY 16″ JOINTER Perfectly straight edges for premium wood joinery. The Can...

Cantek J127LH 12'' Jointer w/ Spiral Cutterhead (3PH)

Price:

$8,900 (USD)

Perfectly straight edges for premium wood joinery. The Cantek J127LH Heavy Duty 12” Jointer is a ...

Cantek J127LH 12'' Jointer w/ Spiral Cutterhead (1PH)

Price:

$9,200 (USD)

Also available- Cantek J127LH 12'' (3PH) ........ $8,900 Perfectly straight edges for premium woo...

Cantek End Matcher EM12

Price:

$57,300 (USD)

CANTEK | EM12 END MATCHER Continuous through feed end matcher producing tongue and groove on floo...

Cantek MX370P Automatic Edgebander with Premilling & Corner Rounding

Price:

$40,800 (USD)

Features The MX370P from Cantek is designed to be a compact, and durable edgebander offered at an...

Cantek MX370M Automatic Edgebander (3PH)

Price:

$30,200 (USD)

Pre-milling & corner rounding in a small footprint. The Cantek MX370M Edgebander is designed to b...

Cantek MX350M Automatic Edgebander with Pre-Milling

Price:

$25,000 (USD)

**Also available MX350 (230V 3PH) High Frequency ............. $33,900 The MX350M from Cantek is ...

Cantek MX340M Automatic Edgebander (1PH or 3PH)

Price:

$18,800 (USD)

**Also available MX340 (230V 1PH) High Frequency ............. $24,500 **Also available MX340 (23...

Cantek MX350 Automatic Edgebander (3PH)

Price:

$33,900 (USD)

CANTEK | MX350 AUTOMATIC EDGEBANDER High quality edge banding results for cabinet parts and case ...

Cantek JEN60 Drawer Notcher- 3 PH

Price:

$11,100 (USD)

Features Designed to notch and drill the underside of a drawer box for mounting undermount drawer...

Cantek JDT75 Automatic Dovetailer- 3 PH 2 HP

Price:

$12,500 (USD)

Features 21500 RPM spindle rotation for an extremely fine finish on dovetail joints High RPM spin...

Cantek JDT65 Manual Dovetailer- 1 PH

Price:

$7,100 (USD)

Features Ideal for drawer production and furniture parts which require high quality dovetail join...

Cantek 21-Spindle Construction Boring Machine HS21T

Price:

$10,200 (USD)

Flexible boring solution for construction drilling, line drilling, and more. The Cantek HS21T 21-...

Felder Sliding Table & Tilting Shaper Model # F700 w/ Steff 2044 Feeder

Price:

$7,500 (USD)

Felder Sliding Table & Tilting Shaper Model # F700

Complete w/ a Steff 2044 Feeder

230V, 3PH

T...

COIMA SHK 3 PLUS Dust Collector

Price:

The SHK Series enclosureless dust collector is designed for the collection of sawdust and is idea...

COIMA SHK 3 Dust Collector

Price:

The SHK Series enclosureless dust collector is designed for the collection of sawdust and is idea...

COIMA BAP-M2.5 Downdraft Sanding Table

Price:

The BAP Series Self-Powered Downdraft Tables are ideal for sanding and finishing operations often...

COIMA SHK 1 Dust Collector

Price:

The SHK Series enclosureless dust collector is designed for the collection of sawdust and is idea...

COIMA SHK 2 Dust Collector

Price:

The SHK Series enclosureless dust collector is designed for the collection of sawdust and is idea...

COIMA SHK 5 Dust Collector

Price:

The SHK Series enclosureless dust collector is designed for the collection of sawdust and is idea...

COIMA SHK 4 Dust Collector

Price:

The SHK Series enclosureless dust collector is designed for the collection of sawdust and is idea...

COIMA SHK 4HS Dust Collector

Price:

The SHK Series enclosureless dust collector is designed for the collection of sawdust and is idea...

COIMA BAP-M3 Downdraft Sanding Table

Price:

The BAP Series Self-Powered Downdraft Tables are ideal for sanding and finishing operations often...

COIMA BAP-M2 Sanding Table

Price:

The BAP Series Self-Powered Downdraft Tables are ideal for sanding and finishing operations often...

Powermatic 20'' Planer

Price:

$2,500 (USD)

Powermatic 20'' Planer

230V, Single Phase

4-blade cutterhead, New bearings in motor, New switch...

Felder Oscillating Edge Sander Model # FS900K

Price:

$3,995 (USD)

Felder Oscillating Edge Sander Model # FS900K

230V, 3 PH

Belt Size 6'' x 86 1/2''

The Felder O...

Evans Pinch Roller 62'' Model #0257- Show Room Machine

Price:

$8,000 (USD)

Evans Pinch Roller 62''

Model #0257

Show Room Machine

Air & 120 Power

This Evans Pinch Roller...

Felder Sliding Panel Saw Model # K975

Price:

$8,000 (USD)

Felder Sliding Panel Saw Model # K975

Scoring blade and tilting arbor

230 V, 3 PH

The Felder S...

Rockwell/ Invicta 16''Jointer

Price:

$5,495 (USD)

New Wire/ New Switches

Cleaned & Painted, 4 knife cutterhead

102'' Bed

The Invicta RJ-42 Joint...

Cantek Edge Sander CT108

Price:

$3,200 (USD)

CANTEK | CT108 EDGE SANDER Ideal edge sander for doors, furniture components, and more. The Cante...

Industrial Cabinet Saw ICS™ (5HP 1ph 230v / 36" T-Glide Fence Assembly)

Price:

$5,489 (USD)

36" Industrial T-Glide Fence System provides smooth operation, precision measurement and sure loc...

Professional Cabinet SawPCS™ (1.75 HP, 1 PH, 36" T-Glide Fence Assembly)

Price:

$3,159 (USD)

36" Professional T-Glide Fence System provides smooth operation, precision measurement and sure l...

Industrial Cabinet Saw ICS™ (7.5HP 3PH 480v / 36" T-Glide Fence Assembly)

Price:

$6,129 (USD)

36" Industrial T-Glide Fence System provides smooth operation, precision measurement and sure loc...

Industrial Cabinet Saw ICS™ (7.5HP 3PH 480v / 52" T-Glide Fence Assembly)

Price:

$6,239 (USD)

52" Industrial T-Glide Fence System provides smooth operation, an expansive work surface, precisi...

Industrial Cabinet Saw ICS™ (7.5HP 3ph 230v / 36" T-Glide Fence Assembly)

Price:

$6,129 (USD)

36" Industrial T-Glide Fence System provides smooth operation, precision measurement and sure loc...

Professional Cabinet SawPCS™ (1.75 HP, 1 PH, 30" Premium Fence)

Price:

$2,863 (USD)

30" Premium Fence System provides smooth operation, precision measurement and sure lockdown witho...

SawStop Jobsite Saw Pro-1.5 HP 1PH

Price:

$1,599 (USD)

JOBSITE SAW PRO The SawStop(R) Jobsite Saw Pro delivers durability, innovation and precision with...

Professional Cabinet SawPCS™ (1.75 HP, 1 PH, 52" T-Glide Fence Assembly)

Price:

$3,259 (USD)

52" Professional T-Glide Fence System provides smooth operation, an expansive work surface, preci...

Contractor Saw CNS™ (30" Premium Fence)

Price:

$1,999 (USD)

30” Premium Fence System provides smooth operation, precision measurement and sure lockdown witho...

Contractor Saw CNS™ (36” T-Glide Fence Assembly)

Price:

$2,295 (USD)

36" Professional T-Glide Fence System provides smooth operation, precision measurement and sure l...

Compact Table Saw CTS™

Price:

$899 (USD)

Exclusive-to-SawStop micro-adjust feature allows you to get the most precise cutting angles possi...

Industrial Cabinet Saw ICS™ (7.5HP 3ph 230v / 52" T-Glide Fence Assembly)

Price:

$6,239 (USD)

52" Industrial T-Glide Fence System provides smooth operation, an expansive work surface, precisi...

Contractor Saw CNS™ (52” T-Glide Fence Assembly)

Price:

$2,395 (USD)

52" Professional T-Glide Fence System provides smooth operation, an expansive work surface, preci...

SawStop Industrial Cabinet Saw- 3HP 1ph (52'' T-Glide)

Price:

$4,969 (USD)

Assembled weight - 52" T-Glide fence system (approximate weight, actual weight has some variance ...

SawStop Industrial Cabinet Saw- 5HP 1ph (36'' T-Glide)

Price:

$5,489 (USD)

FEATURES 36" Industrial T-Glide Fence System provides smooth operation, precision measurement and...

SawStop Industrial Cabinet Saw- 3HP 1ph (36'' T-Glide)

Price:

$4,859 (USD)

FEATURES 36" Industrial T-Glide Fence System provides smooth operation, precision measurement and...

SawStop Industrial Cabinet Saw- 5HP 3ph (36'' T-Glide)

Price:

$5,489 (USD)

FEATURES 36" Industrial T-Glide Fence System provides smooth operation, precision measurement and...

SawStop Industrial Cabinet Saw- 5HP 3ph (52'' T-Glide)

Price:

$5,599 (USD)

FEATURES 52" Industrial T-Glide Fence System provides smooth operation, an expansive work surface...

SawStop Industrial Cabinet Saw- 5HP 1ph (52'' T-Glide)

Price:

$5,599 (USD)

FEATURES 52" Industrial T-Glide Fence System provides smooth operation, an expansive work surface...

Ritter Line Boring Machine

Price:

$1,895 (USD)

Manual Pull Down, New Bits & Fence

The Ritter Line Drill is a robust and efficient machine desig...

Cantek MX340 Automatic Edgebander (1PH)

Price:

$22,900 (USD)

**Also available MX340 (230V 3PH) High Frequency ............. $23,300 CANTEK | MX340 AUTOMATIC E...

Cantek MX340 Automatic Edgebander (3PH)

Price:

$23,300 (USD)

CANTEK | MX340 AUTOMATIC EDGEBANDER High quality edge banding results for cabinet parts and case ...

Cantek MX550AU Portable Edgebander

Price:

$2,800 (USD)

CANTEK | MX550AU PORTABLE EDGEBANDER PACKAGE Take your edgebander to the job site and edgeband st...

Cantek DBS15 Dust Collector (15HP)

Price:

$17,000 (USD)

It is time to clear the air and upgrade your dust system to the next level! The Cantek DBS15 15 H...

Cantek DBS10 Dust Collector (10HP)

Price:

$13,700 (USD)

It is time to clear the air and upgrade your dust system to the next level! The Cantek DBS10 10 H...

Cantek HB600A 24'' Bandsaw Resaw-7.5 HP (3 PH)

Price:

$6,400 (USD)

Features 2 in 1 machine for rip and curve band sawing Bearing blade guide mechanism with side and...

Cantek HB500R 20'' Bandsaw-3 HP (3 PH)

Price:

$4,700 (USD)

Features Production 20″ bandsaw Heavy gauge steel frame ensures stable & vibration free cutting R...

Cantek HB600R 24'' Bandsaw-3 HP (3 PH)

Price:

$5,500 (USD)

Features Production 24″ bandsaw Heavy gauge steel frame ensures stable & vibration free cutting R...

Cantek HB600R 24'' Bandsaw-3 HP (1 PH)

Price:

$5,500 (USD)

**Also available HB600R 24'' Bandsaw 3-HP (3 PH) ...........$5,500 Features Production 24″ bandsa...

Cantek HB600A 24'' Bandsaw Resaw-5 HP (3 PH)

Price:

$6,100 (USD)

**Also available HB600A 24'' Bandsaw Resaw 7.5 HP (3 PH) ...........$6,400 Features 2 in 1 machin...

Cantek HB500R 20'' Bandsaw-3 HP (1 PH)

Price:

$4,700 (USD)

**Also available HB500R 20'' Bandsaw 3-HP (3 PH) ...........$4,500 Features Production 20″ bandsa...

Rockwell/ Delta 20'' Bandsaw

Price:

Rockwell/ Delta 20'' Bandsaw

150'' Blade

3 PH, 230V

New Carter Guides, New Tires, New Wire

Th...

SCM- olympic 500ert Edgebander

Price:

$78,000 (USD)

Olimpic 500 is a complete and versatile edgebander for SME's able to perform different machining ...

SCM- olympic 500te

Price:

$60,000 (USD)

Olimpic 500 is a complete and versatile edgebander for SME's able to perform different machining ...

SCM- olympic 500hp Edgebander

Price:

Olimpic 500 is a complete and versatile edgebander for SME's able to perform different machining ...

SCM Easy Cart

Price:

$18,500 (USD)

Cart for the management of all cleaning operations of the glue pots and the maintenance of the po...

Cantek 43″ Two Head Widebelt Sander (75'' Belt) SR43DA (Rubber Roller-3PH

Price:

$41,900 (USD)

CANTEK | SR43DA 43″ WIDEBELT SANDER A sander that is not only capable but thrives in multiple-shi...

JLT- 8' Miter Buddy System #718A-M2-8-M

Price:

$12,425 (USD)

Includes (2) of the Most Popular Clamping Systems for the Custom Cabinetmaker!! Produce up to 100...

JLT- Miter Door Clamp #717C-M

Price:

$8,350 (USD)

Perfect for the Custom Shop – Produce Miter and Stile & Rail Cabinet Doors on one Single Machine ...

JLT- Triple Door Clamp #717C-TDC

Price:

$11,500 (USD)

Large Capacity, Versatile, and Productive for a Wide Variety of Cabinet Doors and Large Cabinet E...

JLT- Cabinet Door Clamp #717C-DC

Price:

$4,900 (USD)

Most Popular Door Clamp Design – Higher Quality Doors at a Faster Production Pace Clamp and Squar...

JLT- Heavy Duty Entry Door Clamp #79K-10

Price:

$11,500 (USD)

Produce More Solid Wood Entry Doors, Kitchen Cabinet Doors, Window & Door Frames, Face Frames, an...

JLT- Redi-Spreader Glue Applicator #150B

Price:

$1,200 (USD)

Features: The Redi Spreader Glue Applicator is a simple easy to use accessory to the JLT Panel Cl...

JLT- 12′ Panel Clamp #79F-M2-12-PC

Price:

$8,950 (USD)

JLT’s Best Value – Our Most Versatile & Productive Panel Clamp Model PRODUCE up to 72 Edge Glued ...

MiniMax FS41 Elite X 16" Jointer/Planer w/ Xylent Head (1 ph)

Price:

$10,395 (USD)

Surfacing-thicknessing machine for the demanding craftsmen and carpentries, for a high-flexible p...

MiniMax FS41 Elite-S X 16" Jointer/Planer w/ Xylent Head (3PH)

Price:

$19,595 (USD)

Surfacing-thicknessing machine, professional, massive and compact, for a high-flexible production...

MiniMax FS41 Elite-S X 16" Jointer/Planer w/ Xylent Head (1PH)

Price:

$20,195 (USD)

Surfacing-thicknessing machine, professional, massive and compact, for a high-flexible production...

MiniMax CU300C 8.5' Combination Machine w/ 12'' Tersa Head

Price:

$13,985 (USD)

Universal combined machine with all minimax quality, at the most affordable price, ideal for dema...

MiniMax AD 21- Single Phase 21 Hole Construction In-Line Boring Machine

Price:

$7,695 (USD)

Single head multiple boring machine with 21 spindles ideal for craftsmen and professional worksho...

SCM Me 25- 1 PH

Price:

$17,595 (USD)

Automatic edge bander with glue pot to edge band, with great flexibility, with melaminic edges, P...

SCM Me 28et

Price:

$19,985 (USD)

Automatic edge bander with glue pot and pre-milling unit to edge band, with great flexibility, wi...

SCM OMAL Jolly Colla

Price:

$4,420 (USD)

The Jolly Colla is an automatic precision metering glue gun. Equipped with a multifunctional glue...

Mikron Multi-Moulder Model# M645

Price:

$27,980 (USD)

The MIKRON M645 Multi-Moulder is a versatile moulding machine, capable of handling many different...

Mikron Multi-Moulder with Router Model# M652R

Price:

$31,980 (USD)

A New Generation of Moulder... The First-Ever Horizontal Spindle System with Vertical Router Syst...

20'' Delta Bandsaw

Price:

The 20'' Delta Bandsaw is a refurbished piece of industrial equipment ideal for those needing pre...

SCM OMAL 1300 Cube

Price:

The HBD Cube is equipped with 3 Numerical Control axes, 3 vertical and 3 horizontal drilling unit...

SCM OMAL HG2

Price:

The HG2 is an Automatic Drilling and Inserting machine for hinges. The machine has a working fiel...

SCM OMAL HBD 1300 1H

Price:

The HBD 1300 1H is an Open Frame CNC machine to drill, glue and insert dowels with a 1300mm (51”)...

SCM OMAL Velox 1300

Price:

The OMAL Velox 1300 is a Horizontal Bore, Glue and Dowel and numerically controlled machines to d...

SCM Hypsos

Price:

Hypsos is the universal 5-axis machining center with integrated cabin, designed to process comple...

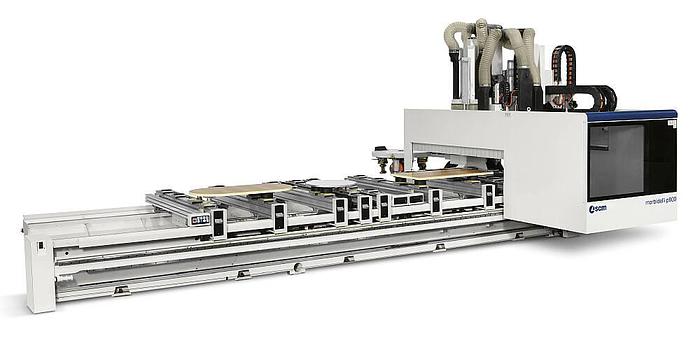

SCM Morbidelli m100/200

Price:

This highly modular machining center provides answers to all the problems associated with woodwor...

SCM Morbidelli m220

Price:

The machining center with double drilling head reduces drilling cycles by 70%, compared to other ...

SCM Accord 500

Price:

accord 500 is the machining center that combines compactness, ease of use and high technology bot...

SCM Accord 600

Price:

accord 600 represents the best design solution that does not compromise on performance when machi...

SCM Accord 30 fx

Price:

Machining center for the production of windows, doors, stairs, solid wood parts and for all those...

SCM Accord 40 fx

Price:

CNC machining center with mobile gantry structure for the production of windows, doors, stairs, s...

SCM Accord 42 fx

Price:

CNC machining center with mobile gantry structure equipped with a machining head consisting of tw...

SCM Accord 50 fx

Price:

5-axis CNC machining center with mobile gantry structure, designed for manufacturing complex-shap...

SCM Accord wd

Price:

Flexible work cell for the production of window and door frames, fitted with automatic loading an...

SCM Morbidelli x50

Price:

morbidelli x50 is an entry level CNC Nesting Machining Centre with wide equipment of routing and ...

SCM Morbidelli x100

Price:

morbidelli x100 belongs to the new generation of Nesting CNC machining centres that meets the nee...

SCM Morbidelli n

Price:

Machining center designed and engineered for woodworking.

Thanks to the unique design and PRO-SP...

SCM Accord nst

Price:

A complete range of CNC machining centers integrated with automatic loading and unloading system ...

SCM Ergon nt

Price:

Cnc machining center with parallel heads designed for a wide range of applications, from panels i...

SCM Morbidelli m220f

Price:

The machining center with double drilling head reduces drilling cycles by 70%, compared to other ...

SCM Morbidelli m600/800f

Price:

Modular machining centers equipped with multi-function aluminium work table, able to guarantee hi...

SCM Accord 25 fxm

Price:

CNC machining center for highly flexible productions requiring superior precision and finish qual...

SCM Accord 30 fxm

Price:

Machining center equipped with the high-performance SCM multifunction worktable in aluminum, for ...

SCM Accord 40 fxm

Price:

CNC machining center with mobile gantry structure, for production of high flexibility and regardl...

SCM Accord 42 fxm

Price:

CNC machining centre with mobile gantry structure and fixed worktable designed for process solid ...

SCM Accord 50 fxm

Price:

5-axis CNC machining center with mobile gantry structure, designed for manufacturing complex-shap...

SCM Return Conveyor

Price:

SCM is pleased to introduce a standard ERC series conveyor to be paired with all edgebander model...

SCM Olimpic k 230 evo

Price:

Easy to use and equipped with everything you need for the complete edge banding of panels, olimpi...

SCM Olimpic 500

Price:

Olimpic 500 is a complete and versatile edgebander for SME's able to perform different machining ...

SCM Stefani kd

Price:

Continuous and versatile solutions for quality machining are the distinctive features of stefani ...

SCM Stefani md

Price:

Perfect joint line and versatility of use with the new SGP glue pot (Smart Glue Pot) and the pre-...

SCM Stefani X

Price:

Industrial edge bander designed to offer the highest quality of processing on any type of panel a...

SCM Stefani S

Price:

stefani s is the single-sided edgebanding machine designed for medium-and large-scale firms and l...

SCM Stefani One

Price:

stefani one is a High End single-sided edgebander designed for large industry and for extra inten...

SCM Stefani psf

Price:

stefani psf is the industrial edgebander dedicated to post-forming or direct postforming process ...

SCM morbidelli p800

Price:

morbidelli p800 is a machining center for drilling, routing and edge treatment for the furniture ...

COIMA FI 10000

Price:

Reliable, powerful, silent…and easy to use.

The FI Series compact enclosed dust collectors are s...

COIMA FI 6000

Price:

Reliable, powerful, silent…and easy to use.

The FI Series compact enclosed dust collectors are s...

COIMA FI 4000

Price:

Reliable, powerful, silent…and easy to use.

The FI Series compact enclosed dust collectors are s...

COIMA F SERIES

Price:

The F-Series Compact Enclosed Dust Collector are designed for efficient filtration in smaller spa...

COIMA FC SERIES

Price:

The FC-Series Compact Enclosed Dust Collector are designed for efficient filtration in smaller sp...

COIMA FB SERIES

Price:

The FB-Series Compact Enclosed Dust Collector are designed for efficient filtration in smaller sp...

SCM Morbidelli m600/m800

Price:

Modular machining centres equipped with multi-function aluminium work table, able to guarantee hi...

SCM Morbidelli m100/200f

Price:

This highly modular machining centre provides answers to all the problems associated with woodwor...

SCM Morbidelli x200/x400

Price:

The new generation of Nesting CNC machining centres meets the needs of a market increasingly orie...

SCM Morbidelli m90

Price:

The new machining center with 3-4 axes technology shares the technological know-how of the "morbi...

SCM Morbidelli n

Price:

Thanks to the unique design and PRO-SPACE safety systems directly integrated onto the machine, a ...

CAP SERIES

Price:

The CAP Series Dust Capture Booth is made of galvanized steel for the capture and extraction of d...

FB SERIES

Price:

The FB-Series Compact Enclosed Dust Collector are designed for efficient filtration in smaller sp...

FC SERIES

Price:

The FC-Series Compact Enclosed Dust Collector are designed for efficient filtration in smaller sp...

F SERIES

Price:

The F-Series Compact Enclosed Dust Collector are designed for efficient filtration in smaller spa...

V 235 NC

Price:

Fully Automatic CNC Mitering System with fixed blade angle. 14" saw blades. Complete with hopper ...

V 2013 NC

Price:

Fully Automatic CNC Mitering System with adjustable blade angle. 12" saw blades. Complete with ho...

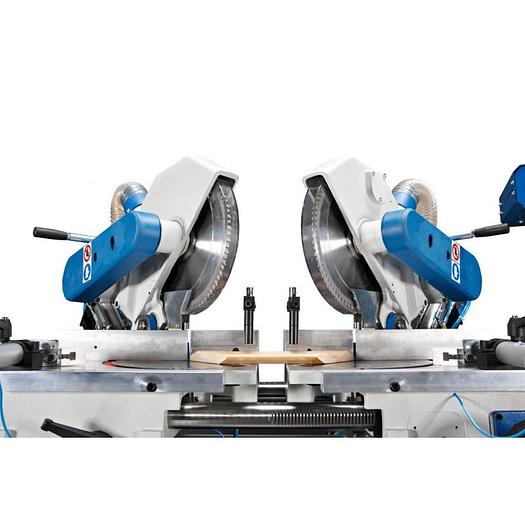

V 235

Price:

Double Mitre Saw for "V" cutting and Picture Frames. Two 14" saw blades, 3 1/2" width capacity. L...

TRF 527

Price:

8.5" Double Mitre Chop Saw 1.5HP Motors Width Cutting Capacity 2" Thickness Capacity 1 1/2" Lengt...

TRF 527 VIS

Price:

8.5" Double Mitre Chop Saw 1.5HP Motors Width Cutting Capacity 2" Thickness Capacity 1 1/2" Lengt...

TR 2A NC

Price:

12" Double Mitre Chop Saw 2.2HP Motors Width Cutting Capacity 6" Thickness Capacity 3 1/2" Length...

TRF 527 NC

Price:

8.5" Double Mitre Chop Saw 1.5HP Motors Width Cutting Capacity 2" Thickness Capacity 1 1/2" Lengt...

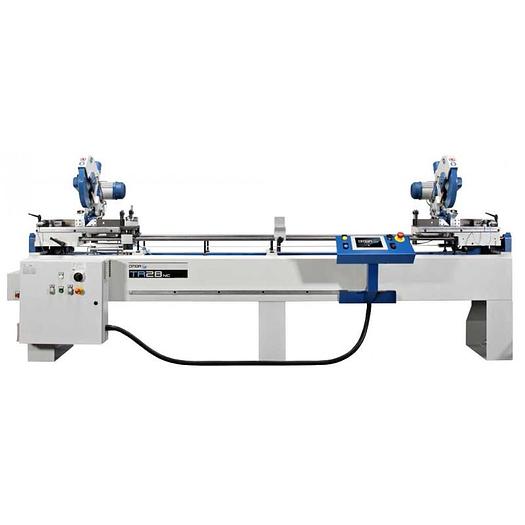

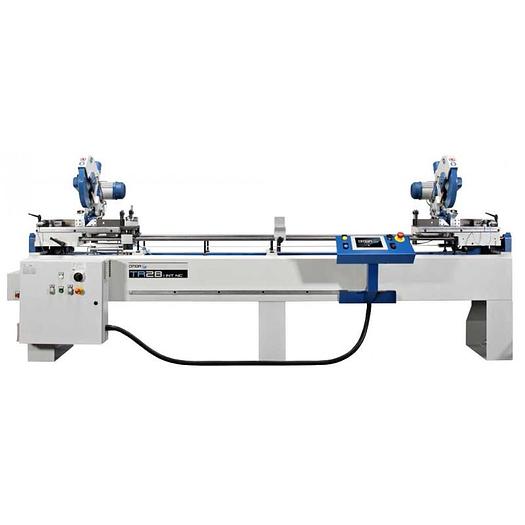

TR 2A

Price:

12" Double Mitre Chop Saw 2.2HP Motors Width Cutting Capacity 6" Thickness Capacity 3 1/2" Length...

TR 2A VIS

Price:

12" Double Mitre Chop Saw 2.2HP Motors Width Cutting Capacity 6" Thickness Capacity 3 1/2" Length...

TR 2B NC

Price:

14" Double Mitre Chop Saw 3HP Motors Width Cutting Capacity 6 5/8" Thickness Capacity 4 1/8" Leng...

TR 2B I INT NC

Price:

14" COMPOUND Double Mitre Chop Saw 4HP Motors Width Cutting Capacity 6 1/2" Thickness Capacity 4 ...

TR 2B VIS

Price:

14" Double Mitre Chop Saw 3HP Motors Width Cutting Capacity 6 5/8" Thickness Capacity 4 1/8" Leng...

TR 2B I INT VIS

Price:

14" COMPOUND Double Mitre Chop Saw 4HP Motors Width Cutting Capacity 7" Thickness Capacity 4 1/8"...

TR 2B

Price:

14" Double Mitre Chop Saw 3HP Motors Width Cutting Capacity 6 5/8" Thickness Capacity 4 1/8" Leng...

RAS 900

Price:

18" Radial Arm Saw 7.5HP Motor, 32 1/4" Cross Cut Capacity, 45" Rip Capacity. Cast Iron Arm. Thes...

OMGA Stop 6 - LH

Price:

Programmable Stop/Positioner System with 6'6" of useable traverse. Left Hand. The OMGA StopTM - 6...

OMGA Stop 13 - LH

Price:

Programmable Stop/Positioner System with 13'1" of useable traverse. Left Hand. The OMGA StopTM - ...

OMGA Stop 10 - LH

Price:

Programmable Stop/Positioner System with 10' of useable traverse. Left Hand. The OMGA StopTM - 10...

OMGA Stop 16 - LH

Price:

Programmable Stop/Positioner System with 16'4" of useable traverse, w/precision linear encoder sy...

RAS 1250

Price:

20" Radial Arm Saw 7.5HP Motor, 44" Cross Cut Capacity, 56" Rip Capacity. Cast Iron Arm. These pr...

OMGA Stop 22 - LH

Price:

Programmable Stop/Positioner System with 22' of useable traverse, w/precision linear encoder syst...

OMGA Stop 6 - RH

Price:

Programmable Stop/Positioner System with 6'6" of useable traverse. Right Hand. The OMGA StopTM - ...

OMGA Stop 16 - RH

Price:

Programmable Stop/Positioner System with 16'4" of useable traverse, w/precision linear encoder sy...

OMGA Stop 10 - RH

Price:

Programmable Stop/Positioner System with 10' of useable traverse. Right Hand. The OMGA StopTM - 1...

OMGA Stop 13 - RH

Price:

Programmable Stop/Positioner System with 13'1" of useable traverse. Right Hand. The OMGA StopTM -...

OMGA Stop 22 - RH

Price:

Programmable Stop/Positioner System with 22' of useable traverse, w/precision linear encoder syst...

T 521 SNC

Price:

Automatic push fed saw for sequenced cutting with 18" saw blade. Last Generation automatic progra...

OPTIMA 120 SNC

Price:

Automatic push fed saw for optimized and pack cutting. The OPTIMA 120 is a Push-Feed Optimizing a...

OPTIMA 60 SNC

Price:

Automatic push fed saw for optimized and pack cutting. The OPTIMA 60 is a Push-Feed Optimizing an...

T 521 ST

Price:

18" Cut-Off Saw 6HP Motor 12 5/8" Cross Cut Capacity Pneumatic adjustable speed pop-up chop saw, ...

OPTIMA 60

Price:

Automatic push fed saw for optimized cutting and defect removal The OPTIMA 60 is a Push-Feed Opti...

OPTIMA 240

Price:

High speed automatic push fed saw for optimized cutting and defect removal. The OPTIMA 240 is a P...

OPTIMA 120 Elite

Price:

High speed automatic push fed saw for optimized cutting and defect removal. OPTIMA 120 Elite is a...

OPTIMA 120

Price:

Automatic push fed saw for optimized cutting and defect removal The OPTIMA 120 is a Push-Feed Opt...

T 2020 NC

Price:

High Speed Automatic Cut-off Saw programmable for optimized cutting of wood stock and defect remo...

T 2030 NC

Price:

Last generation, 800 FPM automatic programmable cut-off saw for optimized cutting of wood stock a...

LEADERMAC | Super Thundermac Moulder SeriesLEADERMAC | Super Thundermac Moulder SeriesCookie and Privacy Settings

Price:

Why Leadermac Super Thundermac Moulder Series? Heavily built fabricated steel frame ensures the p...

CANTEK | JF330A PROFILE GRINDERCANTEK | JF330A PROFILE GRINDERCookie and Privacy Settings

Price:

Why Cantek JF330A Profile Grinder? Powerful 3 HP grinding motor, allowing deep aggressive grindin...

LEADERMAC | SPEEDMAC MOULDER SERIESLEADERMAC | SPEEDMAC MOULDER SERIESCookie and Privacy Settings

Price:

Why Leadermac Speedmac Moulder Series? Heavily built cast iron frame, or fabricated steel frame, ...

LEADERMAC | Thundermac Moulder SeriesLEADERMAC | Thundermac Moulder SeriesCookie and Privacy Settings

Price:

Why Leadermac Thundermac Moulder Series? Heavily built cast iron or fabricated steel frame ensure...

LEADERMAC | Platinum Moulder SeriesLEADERMAC | Platinum Moulder SeriesCookie and Privacy Settings

Price:

Why Leadermac Platinum Moulder Series? A full touch screen control system keeping all history fil...

LEADERMAC | Hypermac Moulder SeriesLEADERMAC | Hypermac Moulder SeriesCookie and Privacy Settings

Price:

Why Leadermac Hypermac Moulder Series? Industrial moulder design with a solid cast iron frame pro...

LEADERMAC | Planermac Moulder SeriesLEADERMAC | Planermac Moulder SeriesCookie and Privacy Settings

Price:

Why Leadermac Planermac Moulder Series? Heavily built fabricated steel frame ensures the producti...

DM200RHC

Price:

14" Double end trim mitre saw TBA Specifications Double end trim mitre saw 2 H.P. 3phase Magnetic...

LEADERMAC | Compact Moulder SeriesLEADERMAC | Compact Moulder SeriesCookie and Privacy Settings

Price:

Why Leadermac Compact Moulder Series? Industrial moulder design with a solid cast iron frame prod...

LEADERMAC | Smartmac Moulder SeriesLEADERMAC | Smartmac Moulder SeriesCookie and Privacy Settings

Price:

Why Leadermac Smartmac Moulder Series? Industrial moulder design with a solid cast iron frame pro...

UCS222-A

Price:

22" Blade capacity semi automatic cut-off saw The CTD up-cut saws are engineered for accurate, fa...

DM400

Price:

16" Double end trim mitre saw The DM400 uses two standard 400 Series saw heads. See 400 Series fe...

UCS218-A

Price:

18" Blade capacity semi automatic cut-off saw These up-cut saws are engineered for accurate, fast...

DM200R

Price:

12" Double end trim mitre saw TBA Specifications Double end trim mitre saw 2 H.P. 3phase Magnetic...

CDM300R

Price:

12" Compound double end trim mitre saw The CTD Model CDM300R is our most versatile 12" Double End...

CDM60

Price:

16" Compound double end trim mitre saw The CTD Model CDM60 offers a maximum of flexibility and cu...

CM60

Price:

16" Mitre & Compound cut-off saw These saws cut your costs, are accurate, rugged, and give long l...

N90S

Price:

18" Special staggered blade toe notching saw The Model N90 has been designed for a variety of hea...

N90

Price:

16" Vertical frame and notching saw The Model N90 has been designed for a variety of heavy duty c...

CS-14

Price:

14" Mitre cold saw CTD Machines new CS-14 is a 14” cold saw with a dual speed motor winding. This...

D45AX 14

Price:

CTD Model D45AX14 Frame & Notching Saw The CTD 400 Series Cut Off Saws are designed for heavy dut...

D45AX

Price:

12" Fixed head double mitre saw The D45 is popular world wide because of its unique features, low...

CS-12

Price:

12" Mitre cold saw CTD Machines new CS-12AF is a 12” cold saw with a dual speed motor winding. Th...

F255

Price:

12" Straight cut-off saw The Model F255R uses the same sawhead as the M25R, but cuts 90° only. Sp...

M25RHC

Price:

14" Mitre cut-off saw This rugged, accurate heavy duty industrial indexing mitre cut-off saw uses...

Jobsite Saw Pro JSS™

Price:

$1,599 (USD)

Class-Leading Table Depth: 24 5/8” table depth allows a larger surface to make safe and accurate ...

M25R

Price:

12" Mitre cut-off saw This rugged, accurate heavy duty industrial indexing mitre cut-off saw uses...

UCS 222MQ

Price:

22" Blade capacity semi automatic Miter cut-off saw, Manual, Quill controlled, or Digital option ...

UCS 222M

Price:

22" Blade capacity semi automatic Miter cut-off saw, Manual, Quill controlled, or Digital option ...

UCS 218

Price:

18" Blade capacity semi automatic cut-off saw These up-cut saws are engineered for accurate, fast...

UCS 222

Price:

22" Blade capacity semi automatic cut-off saw The CTD up-cut saws are engineered for accurate, fa...

NT-UCS24R-AS UP CUT SAW RIGHT HAND ALUMINUM SERIES

Price:

NT-UCS24R-AS UP CUT SAW RIGHT HAND ALUMINUM SERIES The NT UCS24R-AS Up Cut Saw is a step up in ca...

NT-UCS24L-AS UP CUT SAW LEFT HAND ALUMINUM SERIES

Price:

NT-UCS24L-AS UP CUT SAW LEFT HAND ALUMINUM SERIES The NT UCS24L-AS Up Cut Saw is a step up in cap...

NT-UCS30L UP CUT SAW LEFT HAND

Price:

NT-CS30L UP CUT SAW LEFT HAND NT-CS30L UP CUT SAW LEFT HAND Main motor hp: 15 HP | Voltage, frequency: 230/4...

NT-880S-HSK SHAPER WITH SLIDE

Price:

Northtech shapers are built for industrial use. The NT-880SHSK is our 15HP quick tool change shap...

NT-UCS20R UP CUT SAW RIGHT HAND

Price:

The NT UCS20R Up Cut Saw is in the middle of the family of Northtech Up Cut Saws. Upcut Saws hous...

NT-880-HSK SHAPER

Price:

Northtech shapers are built for industrial use. The NT-8800HSK is our 10HP quick tool change shap...

NT-UCS18R-AS UP CUT SAW RIGHT HAND ALUMINUM SERIES

Price:

The NT UCS18R-AS Up Cut Saw is a popular saw for cutting aluminum. Upcut Saws house the blade ins...

NT-UCS20L UP CUT SAW LEFT HAND

Price:

The NT UCS20L Up Cut Saw is in the middle of the family of Northtech Up Cut Saws. Upcut Saws hous...

NT-800T SHAPER WITH TILTING SPINDLE

Price:

The NT 800T is the 800 series shaper equipped with a tilting spindle. The 800 series features a l...

NT-UCS18R UP CUT SAW RIGHT HAND

Price:

The NT UCS18R Up Cut Saw is the most popular model in the Northtech Up Cut Saw family. Up Cut Saw...

NT-UCS18L UP CUT SAW LEFT HAND

Price:

The NT UCS18L Up Cut Saw is the most popular model in the Northtech Up Cut Saw family. Upcut Saws...

NT-UCS18L-AS UP CUT LEFT HAND SAW ALUMINUM SERIES

Price:

The NT UCS18L-AS Up Cut Saw is a popular saw for cutting aluminum. Up cut Saws house the blade in...

NT-900C WIDE BELT SANDER

Price:

The NT-900C single combination head wide belt sander has a 36″ working width and comes standard w...

NT-UCS14R UP CUT SAW RIGHT HAND

Price:

The NT UCS14R Up Cut Saw is the baby of the Northtech Up Cut Saw family. Upcut Saws house the bla...

NT-8-900RC WIDE BELT SANDER

Price:

NT-8-900RC WIDE BELT SANDER The NT 8-900RC roller combination head wide belt sander has a 36″ wor...

NT-8-600RC WIDE BELT SANDER 24″

Price:

NT-600RC WIDE BELT SANDER 24″ 25X75″ SANDING BELT NT-600RC WIDE BELT SANDER 24″ 25X75″ SANDING BELT Machine ...

NT-9-1100RC WIDE BELT SANDER

Price:

NT-9-1100RC WIDE BELT SANDER NT-9-1100RC WIDE BELT SANDER Machine hp: 37 HP | Voltage, frequency: 230/460 Vo...

NT-770S-HSK SHAPER WITH SLIDE

Price:

Northtech shapers are built for industrial use. The NT-770HSK is our 10HP quick tool change shape...

NT-770-HSK SHAPER

Price:

Northtech shapers are built for industrial use. The NT-770HSK is our 10HP quick tool change shape...

NT-735TS SHAPER WITH TILTING SPINDLE, SLIDING TABLE

Price:

The NT 735TS is the 735 shaper equipped with a sliding table and tilting spindle. The 735 series ...

NT-735T SHAPER WITH TILTING SPINDLE

Price:

The NT 735T is the 735 shaper equipped with a tilting spindle. The 735 series features a large st...

NT-UCS14L UP CUT SAW LEFT HAND

Price:

The NT UCS14L Up Cut Saw is the baby of the Northtech Up Cut Saw family. Upcut Saws house the bla...

NT-CS36L UP CUT SAW LEFT HAND

Price:

The NT CS36L Up Cut Saw is the largest cross cut saw we offer. Left handed Up Cut Saws have the b...

NT-CS36R UP CUT SAW RIGHT HAND

Price:

The NT CS36R Up Cut Saw is the largest cross cut saw we offer. Upcut Saws house the blade inside ...

NT-HRR3 HORIZONTAL REMAN RESAW

Price:

The NT-HRR3 is a unique horizontal resaw with a vertical trough feeding system that is used to si...

NT-CS30R UP CUT SAW RIGHT HAND

Price:

The NT CS30R Up Cut Saw is the second largest cross cut saw we offer. Upcut Saws house the blade ...

NT-8-1300RC WIDE BELT SANDER

Price:

NT-8-1300RC WIDE BELT SANDER The NT-8-1300RC is two head wide belt sander that has a 51″ working ...

NT-600C WIDE BELT SANDER

Price:

The NT-600C single combination head wide belt sander has a 24″ working width and comes standard w...

NT-8-1100RC WIDE BELT SANDER

Price:

NT-8-1100RC WIDE BELT SANDER The NT-8-1100RC is two head wide belt sander that has a 43″ working ...

NT-1300C WIDE BELT SANDER

Price:

NT-1300C WIDE BELT SANDER The NT-1300C single combination head wide belt sander has a 51″ working...

NT-ES972DE EDGE SANDER DOUBLE TABLE

Price:

Northtech offers a large family of industrial grade edge sanders. The NT-ES9672DE offers our long...

NT-ES960SE EDGE SANDER SINGLE TABLE BELT 9″ X 158″, PLATEN 9.5″ X 60″

Price:

Northtech offers a large family of industrial grade edge sanders. The NT-ES960SE is a popular siz...

NT-735S SHAPER WITH SLIDING TABLE

Price:

The NT 735S is the 735 shaper equipped with a sliding table. The 735 series features a large stab...

NT-ES960DE EDGE SANDER DOUBLE TABLE

Price:

Northtech offers a large family of industrial grade edge sanders. The NT-ES960DE is a popular siz...

NT-735M SHAPER

Price:

The NT 735 shaper is one of the best built shapers available. Matching the powerful 10hp intercha...

NT-ES948SE EDGE SANDER SINGLE TABLE

Price:

NT-ES948SE EDGE SANDER SINGLE TABLE Northtech offers a large family of industrial grade edge sand...

NT-735LT SHAPER LONG BED WITH TILTING SPINDLE

Price:

NT-735LT SHAPER WITH LONG BED TILTING SPINDLE The NT 735LT shaper is our heavy duty 735 series ma...

NT-625TS SHAPER WITH TILTING SPINDLE, SLIDING TABLE

Price:

NT-625TS SHAPER WITH TILTING SPINDLE, SLIDING TABLE The NT 625TS is the 625 shaper equipped with ...

NT-S5230 MOULDER 5 HEAD

Price:

NT-S5230 MOULDER 5 HEAD The NT S5230 is a compact heavy duty 5 head moulder with large moulder ca...