Advanced Filters

Category

Subcategory

Manufacturer

Condition

Cantek P30 5′ Sliding Table Saw (1PH/3PH)

Price:

$8,900 (USD)

Powerful features in a small footprint sliding panel saw. The Cantek P30 5′ Sliding Table Saw is ...

Cantek Oscillating Edge Sander Model PW120E

Price:

$7,800 (USD)

Versatile edge sander for doors, drawer boxes and more. The Cantek PW120E Oscillating Edge Sander...

Cantek Manual Oscillating Edge Brush Sander E6

Price:

$4,900 (USD)

CANTEK | E6 OSCILLATING EDGE BRUSH SANDER Oscillating brush sander for sanding the edges of cabin...

Cantek Edge Sander CT108

Price:

$3,200 (USD)

CANTEK | CT108 EDGE SANDER Ideal edge sander for doors, furniture components, and more. The Cante...

Cantek P305 10′ Sliding Table Saw (1PH)

Price:

$10,500 (USD)

Powerful features in a small footprint sliding panel saw. The Cantek P305 10’ Sliding Table Saw i...

Cantek P305 10′ Sliding Table Saw (3PH)

Price:

$10,200 (USD)

Powerful features in a small footprint sliding panel saw. The Cantek P305 10’ Sliding Table Saw i...

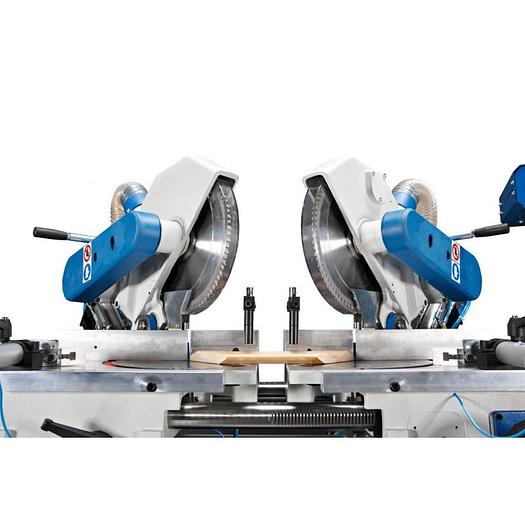

Cantek PCM610 24'' Miter Cutting Chop Saw

Price:

$28,100 (USD)

CANTEK | PCM610 24″ MITER CUT-OFF SAW Large capacity miter cut-off saw is built for production. T...

Cantek PCM508 20'' Miter Cutting Chop Saw

Price:

$17,800 (USD)

CANTEK | PCM508 20″ MITER CUT-OFF SAW Large capacity miter cut-off saw is built for production. T...

Cantek PCS30 30'' Pneumatic Chop Saw w/ Foot Pedal Control (LH or RH)

Price:

$18,800 (USD)

CANTEK | PCS30 30″ PNEUMATIC CUT-OFF SAW Large capacity crosscutting solution. The Cantek PCS30 3...

Cantek PCS36 36'' Pneumatic Chop Saw w/ Foot Pedal Control (LH or RH)

Price:

$26,800 (USD)

CANTEK | PCS36 36″ PNEUMATIC CUT-OFF SAW Large capacity crosscutting solution. The Cantek PCS36 3...

Cantek PCS24 24'' Pneumatic Chop Saw w/ Foot Pedal Control (LH or RH)

Price:

$13,800 (USD)

Large capacity crosscutting solution. The Cantek PCS24 24” pneumatic chop saw is the ideal soluti...

Cantek PCS18M 18'' Non-Ferrous Pneumatic Chop Saw w/ Foot Pedal (LH or RH)

Price:

$9,700 (USD)

PCS18MD 18'' Non-Ferrous Pneumatic Chop Saw w/ Dual Push Button Control (LH or RH) .........add $...

Cantek PCS18 18'' Pneumatic Chop Saw w/ Foot Pedal Control (LH or RH)

Price:

$7,300 (USD)

PCS18D 18'' Pneumatic Chop Saw w/ Dual Push Button Control (LH or RH) .........add 520 Or 460 V …...

Cantek PCS14 14'' Pneumatic Chop Saw w/ Foot Pedal Control (LH or RH)

Price:

$6,700 (USD)

PCS14D 14'' Pneumatic Chop Saw w/ Dual Push Button Control (LH or RH) ........ add $490 Or 460V …...

Cantek Pneumatic Overarm Pin Router SR750

Price:

$13,900 (USD)

CANTEK | SR750 PNEUMATIC OVERARM PIN ROUTER There is nothing like an Overarm Router for productio...

Cantek 26″ Planer CM626 (3PH)

Price:

$23,800 (USD)

CANTEK | CM626 26″ PLANER Powerful 26” heavy duty planer that fits your everyday needs. The Cante...

Cantek 32″ Planer P815HV (3PH)

Price:

$29,500 (USD)

CANTEK | P815HV 32″ PLANER Powerful heavy duty 32” planer that fits your everyday needs. The Cant...

Cantek 24″ Planer P630HV (3PH)

Price:

$16,800 (USD)

Powerful heavy duty 24” planer that fits your everyday needs. The Cantek P630HV 24″ Planer has a ...

Cantek 20″ Planer P20HV (3PH)

Price:

$8,200 (USD)

Compact and economically priced 20” planer with spiral cutterhead. The Cantek P20HV 20” Planer ha...

Cantek 20″ Planer P20HV(1PH)

Price:

$9,000 (USD)

Compact and economically priced 20” planer with spiral cutterhead. The Cantek P20HV 20” Planer ha...

Cantek 24″ Planer P24HV (3PH)

Price:

$11,600 (USD)

Compact and economically priced 24” planer with spiral cutterhead. The Cantek P24HV 24” Planer ha...

Cantek 20″ Planer P508HV (3PH)

Price:

$14,100 (USD)

Powerful heavy duty 20” planer that fits your everyday needs. The Cantek P508HV 20” Planer has a ...

Cantek MX370M Automatic Edgebander (3PH)

Price:

$28,200 (USD)

Pre-milling & corner rounding in a small footprint. The Cantek MX370M Edgebander is designed to b...

Cantek 21-Spindle Construction Boring Machine HS21T

Price:

$9,600 (USD)

Flexible boring solution for construction drilling, line drilling, and more. The Cantek HS21T 21-...

SCM- olympic 300te Single-Sided Automatic Edgebander

Price:

$49,000 (USD)

Compact edge bander with a sturdy framework that guarantees reliability and repeatability.

Thank...

Industrial Cabinet Saw ICS™ (5HP 1ph 230v / 36" T-Glide Fence Assembly)

Price:

$5,489 (USD)

36" Industrial T-Glide Fence System provides smooth operation, precision measurement and sure loc...

Professional Cabinet SawPCS™ (1.75 HP, 1 PH, 36" T-Glide Fence Assembly)

Price:

$3,159 (USD)

36" Professional T-Glide Fence System provides smooth operation, precision measurement and sure l...

Industrial Cabinet Saw ICS™ (7.5HP 3PH 480v / 36" T-Glide Fence Assembly)

Price:

$6,129 (USD)

36" Industrial T-Glide Fence System provides smooth operation, precision measurement and sure loc...

Industrial Cabinet Saw ICS™ (7.5HP 3PH 480v / 52" T-Glide Fence Assembly)

Price:

$6,239 (USD)

52" Industrial T-Glide Fence System provides smooth operation, an expansive work surface, precisi...

Industrial Cabinet Saw ICS™ (7.5HP 3ph 230v / 36" T-Glide Fence Assembly)

Price:

$6,129 (USD)

36" Industrial T-Glide Fence System provides smooth operation, precision measurement and sure loc...

Professional Cabinet SawPCS™ (1.75 HP, 1 PH, 30" Premium Fence)

Price:

$2,863 (USD)

30" Premium Fence System provides smooth operation, precision measurement and sure lockdown witho...

SawStop Jobsite Saw Pro-1.5 HP 1PH

Price:

$1,599 (USD)

JOBSITE SAW PRO The SawStop(R) Jobsite Saw Pro delivers durability, innovation and precision with...

Professional Cabinet SawPCS™ (1.75 HP, 1 PH, 52" T-Glide Fence Assembly)

Price:

$3,259 (USD)

52" Professional T-Glide Fence System provides smooth operation, an expansive work surface, preci...

Contractor Saw CNS™ (30" Premium Fence)

Price:

$1,999 (USD)

30” Premium Fence System provides smooth operation, precision measurement and sure lockdown witho...

Contractor Saw CNS™ (36” T-Glide Fence Assembly)

Price:

$2,295 (USD)

36" Professional T-Glide Fence System provides smooth operation, precision measurement and sure l...

Compact Table Saw CTS™

Price:

$899 (USD)

Exclusive-to-SawStop micro-adjust feature allows you to get the most precise cutting angles possi...

Industrial Cabinet Saw ICS™ (7.5HP 3ph 230v / 52" T-Glide Fence Assembly)

Price:

$6,239 (USD)

52" Industrial T-Glide Fence System provides smooth operation, an expansive work surface, precisi...

Contractor Saw CNS™ (52” T-Glide Fence Assembly)

Price:

$2,395 (USD)

52" Professional T-Glide Fence System provides smooth operation, an expansive work surface, preci...

SawStop Industrial Cabinet Saw- 3HP 1ph (52'' T-Glide)

Price:

$4,969 (USD)

Assembled weight - 52" T-Glide fence system (approximate weight, actual weight has some variance ...

SawStop Industrial Cabinet Saw- 5HP 1ph (36'' T-Glide)

Price:

$5,489 (USD)

FEATURES 36" Industrial T-Glide Fence System provides smooth operation, precision measurement and...

SawStop Industrial Cabinet Saw- 3HP 1ph (36'' T-Glide)

Price:

$4,859 (USD)

FEATURES 36" Industrial T-Glide Fence System provides smooth operation, precision measurement and...

SawStop Industrial Cabinet Saw- 5HP 3ph (36'' T-Glide)

Price:

$5,489 (USD)

FEATURES 36" Industrial T-Glide Fence System provides smooth operation, precision measurement and...

SawStop Industrial Cabinet Saw- 5HP 3ph (52'' T-Glide)

Price:

$5,599 (USD)

FEATURES 52" Industrial T-Glide Fence System provides smooth operation, an expansive work surface...

SawStop Industrial Cabinet Saw- 5HP 1ph (52'' T-Glide)

Price:

$5,599 (USD)

FEATURES 52" Industrial T-Glide Fence System provides smooth operation, an expansive work surface...

Steff Supersonic 3 Power Feeder

Price:

$1,850 (USD)

(3) Rollers Variable speed up to 82 feet per minute (108.5 FPM with optional gears) Quick forward...

Steff Power Feeder; Model #: 2038

Price:

$1,350 (USD)

(3) Rollers and (8) speeds of 6-13-18-21-36-42-54-102 FPM 1 HP motor 4-3/4" roller diameter 2-1/4...

Steff Supersonic 4 Power Feeder

Price:

$1,950 (USD)

(4) Rollers Variable speed up to 82 feet per minute (108.5 FPM with optional gears) Quick forward...

Ritter Line Boring Machine

Price:

$1,895 (USD)

Manual Pull Down, New Bits & Fence

The Ritter Line Drill is a robust and efficient machine desig...

Steff Power Feeder; Model #: 2034

Price:

$1,100 (USD)

(3) Rollers and (4) speeds of 13-26-36-72 FPM 1 HP motor 4-3/4" roller diameter 2-1/4" roller wid...

Cantek Multi Blade Gang Ripsaw MRS300

Price:

$37,200 (USD)

CANTEK | MRS300 MULTI BLADE GANG RIPSAW A powerful multi ripsaw for the most demanding ripping ap...

Cantek 14'' Glue Line Rip Saw C14RS

Price:

$29,100 (USD)

Large capacity glue line ripsaw with precision straight line results. The Cantek C14RS Straight L...

Cantek 13'' Glue Line Rip Saw SRS330 (230V/ 460V)

Price:

$23,500 (USD)

Precision glue joint ripsaw built for power and speed. The Cantek SRS330 Straight Line Glue Joint...

Cantek 12'' Glue Line Rip Saw C12RSH

Price:

$20,400 (USD)

Save time and speed up production in your ripping operations. The Cantek C12RSH Straight Line Glu...

Cantek 10'' Straight Line Rip Saw 303S

Price:

$14,200 (USD)

Save time and speed up production in your ripping operations. The Cantek 303S single blade ripsaw...

Cantek 30'' X 8'' Double Surface Planer GT760ARD-8

Price:

$44,500 (USD)

Plane your material efficiently in a single pass. The Cantek GT760ARD 30″ Double Surface Planer h...

Cantek 16'' X 6.7'' Double Surface Planer GT400BRD

Price:

$26,900 (USD)

CANTEK | GT400BRD 16″ DOUBLE SURFACE PLANER Plane your material efficiently in a single pass. The...

Cantek 25'' X 8'' Double Surface Planer GT635ARD-8

Price:

$38,000 (USD)

CANTEK | GT635ARD 25″ DOUBLE SURFACE PLANER Plane your material efficiently in a single pass. The...

Cantek 4-Sided Planer Moulder M412 (3PH)

Price:

$22,900 (USD)

CANTEK | M412 4-SIDED PLANER MOULDER Economical 4-Sided Planer Moulder Solution for the Small Sho...

Cantek J168LH 16'' Jointer w/ Spiral Cutterhead (3PH)

Price:

$12,200 (USD)

CANTEK | J168LH HEAVY DUTY 16″ JOINTER Perfectly straight edges for premium wood joinery. The Can...

Cantek J127LH 12'' Jointer w/ Spiral Cutterhead (3PH)

Price:

$8,400 (USD)

Perfectly straight edges for premium wood joinery. The Cantek J127LH Heavy Duty 12” Jointer is a ...

Cantek J127LH 12'' Jointer w/ Spiral Cutterhead (1PH)

Price:

$8,700 (USD)

Also available- Cantek J127LH 12'' (3PH) ........ $8,400 Perfectly straight edges for premium woo...

Cantek MX350 Automatic Edgebander (3PH)

Price:

$31,700 (USD)

CANTEK | MX350 AUTOMATIC EDGEBANDER High quality edge banding results for cabinet parts and case ...

Cantek MX340 Automatic Edgebander (1PH)

Price:

$22,900 (USD)

**Also available MX340 (230V 3PH) High Frequency ............. $23,300 CANTEK | MX340 AUTOMATIC E...

Cantek MX340 Automatic Edgebander (3PH)

Price:

$23,300 (USD)

CANTEK | MX340 AUTOMATIC EDGEBANDER High quality edge banding results for cabinet parts and case ...

Cantek MX370P Automatic Edgebander with Premilling & Corner Rounding

Price:

$38,300 (USD)

Features The MX370P from Cantek is designed to be a compact, and durable edgebander offered at an...

Cantek MX550AU Portable Edgebander

Price:

$2,800 (USD)

CANTEK | MX550AU PORTABLE EDGEBANDER PACKAGE Take your edgebander to the job site and edgeband st...

Cantek MX350M Automatic Edgebander with Pre-Milling

Price:

$23,500 (USD)

**Also available MX350 (230V 3PH) High Frequency ............. $31,700 The MX350M from Cantek is ...

Cantek MX340M Automatic Edgebander (1PH or 3PH)

Price:

$17,700 (USD)

**Also available MX340 (230V 1PH) High Frequency ............. $22,900 **Also available MX340 (23...

Cantek DBS15 Dust Collector (15HP)

Price:

$17,000 (USD)

It is time to clear the air and upgrade your dust system to the next level! The Cantek DBS15 15 H...

Cantek DBS10 Dust Collector (10HP)

Price:

$13,700 (USD)

It is time to clear the air and upgrade your dust system to the next level! The Cantek DBS10 10 H...

Cantek HB600A 24'' Bandsaw Resaw-7.5 HP (3 PH)

Price:

$6,400 (USD)

Features 2 in 1 machine for rip and curve band sawing Bearing blade guide mechanism with side and...

Cantek HB500R 20'' Bandsaw-3 HP (3 PH)

Price:

$4,700 (USD)

Features Production 20″ bandsaw Heavy gauge steel frame ensures stable & vibration free cutting R...

Cantek HB600R 24'' Bandsaw-3 HP (3 PH)

Price:

$5,500 (USD)

Features Production 24″ bandsaw Heavy gauge steel frame ensures stable & vibration free cutting R...

Cantek HB600R 24'' Bandsaw-3 HP (1 PH)

Price:

$5,500 (USD)

**Also available HB600R 24'' Bandsaw 3-HP (3 PH) ...........$5,500 Features Production 24″ bandsa...

Cantek HB600A 24'' Bandsaw Resaw-5 HP (3 PH)

Price:

$6,100 (USD)

**Also available HB600A 24'' Bandsaw Resaw 7.5 HP (3 PH) ...........$6,400 Features 2 in 1 machin...

Cantek HB500R 20'' Bandsaw-3 HP (1 PH)

Price:

$4,700 (USD)

**Also available HB500R 20'' Bandsaw 3-HP (3 PH) ...........$4,500 Features Production 20″ bandsa...

Blum Hinge Machine Model # FA01489

Price:

Blum Hinge Machine Model # FA01489

230V, Single Phase

Local Pickup Only

The refurbished Blum H...

Powermatic 20'' Planer

Price:

Powermatic 20'' Planer

230V, Single Phase

4-blade cutterhead, New bearings in motor, New switch...

Rockwell/ Delta 20'' Bandsaw

Price:

Rockwell/ Delta 20'' Bandsaw

150'' Blade

3 PH, 230V

New Carter Guides, New Tires, New Wire

Th...

Evans Pinch Roller 62'' Model #0257- Show Room Machine

Price:

Evans Pinch Roller 62''

Model #0257

Show Room Machine

Air & 120 Power

This Evans Pinch Roller...

Felder Oscillating Edge Sander Model # FS900K

Price:

Felder Oscillating Edge Sander Model # FS900K

230V, 3 PH

Belt Size 6'' x 86 1/2''

The Felder O...

Felder Sliding Panel Saw Model # K975

Price:

Felder Sliding Panel Saw Model # K975

Scoring blade and tilting arbor

230 V, 3 PH

The Felder S...

Felder Sliding Table & Tilting Shaper Model # F700 w/ Steff 2044 Feeder

Price:

Felder Sliding Table & Tilting Shaper Model # F700

Complete w/ a Steff 2044 Feeder

230V, 3PH

T...

SCMI Widebelt Sander Model # Sandya 300

Price:

$26,900 (USD)

SCMI Widebelt Sander Model # Sandya 300

2-head 43'' Sander

One Owner Machine, In Great Shape

2...

SCM- olympic 500ert Edgebander

Price:

$78,000 (USD)

Olimpic 500 is a complete and versatile edgebander for SME's able to perform different machining ...

SCM- olympic 500te

Price:

$60,000 (USD)

Olimpic 500 is a complete and versatile edgebander for SME's able to perform different machining ...

SCM- olympic 500hp Edgebander

Price:

Olimpic 500 is a complete and versatile edgebander for SME's able to perform different machining ...

SCM- olympic 300ert Single-Sided Automatic Edgebander

Price:

$65,000 (USD)

Compact edge bander with a sturdy framework that guarantees reliability and repeatability.

Thank...

SCM Easy Cart

Price:

$18,500 (USD)

Cart for the management of all cleaning operations of the glue pots and the maintenance of the po...

SCM- olympic 300b Single-Sided Automatic Edgebander

Price:

$39,000 (USD)

Compact edge bander with a sturdy framework that guarantees reliability and repeatability.

Thank...

Cantek 43″ Two Head Widebelt Sander (75'' Belt) SR43DA (Rubber Roller-3PH

Price:

$41,900 (USD)

CANTEK | SR43DA 43″ WIDEBELT SANDER A sander that is not only capable but thrives in multiple-shi...

Cantek 24″ Widebelt Sander (60" Belt) S251 (3PH)

Price:

$10,900 (USD)

CANTEK | S251 24″ WIDEBELT SANDER A robust widebelt sander with minimal footprint. The Cantek S25...

Cantek 24″ Widebelt Sander (60" Belt) S251 (1PH)

Price:

$12,500 (USD)

CANTEK | S251 24″ WIDEBELT SANDER A robust widebelt sander with minimal footprint. The Cantek S25...

Cantek 36″ Widebelt Sander (60" Belt) S371 (3PH)

Price:

$15,990 (USD)

CANTEK | S371 36″ WIDEBELT SANDER Dependable, consistent sanding results with a robust design tha...

CANTEK | S431 43″ WIDEBELT SANDER

Price:

$22,500 (USD)

Dependable, consistent sanding results at an affordable price. The Cantek S431 43″ Widebelt Sande...

Cantek JDT75 Automatic Dovetailer- 3 PH 2 HP

Price:

$11,800 (USD)

Features 21500 RPM spindle rotation for an extremely fine finish on dovetail joints High RPM spin...

JLT- 8' Miter Buddy System #718A-M2-8-M

Price:

$12,425 (USD)

Includes (2) of the Most Popular Clamping Systems for the Custom Cabinetmaker!! Produce up to 100...

JLT- Miter Door Clamp #717C-M

Price:

$8,350 (USD)

Perfect for the Custom Shop – Produce Miter and Stile & Rail Cabinet Doors on one Single Machine ...

JLT- Triple Door Clamp #717C-TDC

Price:

$11,500 (USD)

Large Capacity, Versatile, and Productive for a Wide Variety of Cabinet Doors and Large Cabinet E...

JLT- Cabinet Door Clamp #717C-DC

Price:

$4,900 (USD)

Most Popular Door Clamp Design – Higher Quality Doors at a Faster Production Pace Clamp and Squar...

JLT- Heavy Duty Entry Door Clamp #79K-10

Price:

$11,500 (USD)

Produce More Solid Wood Entry Doors, Kitchen Cabinet Doors, Window & Door Frames, Face Frames, an...

JLT- Redi-Spreader Glue Applicator #150B

Price:

$1,200 (USD)

Features: The Redi Spreader Glue Applicator is a simple easy to use accessory to the JLT Panel Cl...

JLT- 12′ Panel Clamp #79F-M2-12-PC

Price:

$8,950 (USD)

JLT’s Best Value – Our Most Versatile & Productive Panel Clamp Model PRODUCE up to 72 Edge Glued ...

SCM Minimax s 45n Bandsaw

Price:

$3,785 (USD)

The minimax s 45n is an SCM Group made 2.5hp motor bandsaw. With over 20 years of service to the ...

SCM MiniMax S440P- Single Phase Bandsaw

Price:

$5,385 (USD)

PROFESSIONAL SERIES Massive, high-precision, professional band saws for serious woodworkers and p...

SCM MiniMax SC2 Classic 5.5' - 1ph Manual Sliding Table Saw

Price:

$5,995 (USD)

The precise, cost-effective and compact circular saw with tilting blade for the D.I.Y. woodworker...

Minimax T124 Wood Turning Lathe Sander

Price:

$5,995 (USD)

Strong base ensures maximum reliability and top precision turning. Copier ideal for small batches...

MiniMax LS-2500 Sander -3PH

Price:

$8,895 (USD)

Belt sander with double gooseneck for craftsmen and professional workshops. Advantages Excellent ...

MiniMax S640P- 1 Phase Bandsaw

Price:

$7,985 (USD)

PROFESSIONAL SERIES Massive, high-precision, professional band saws for serious woodworkers and p...

MiniMax FS41 Elite X 16" Jointer/Planer w/ Xylent Head (1 ph)

Price:

$10,395 (USD)

Surfacing-thicknessing machine for the demanding craftsmen and carpentries, for a high-flexible p...

MiniMax FS41 Elite-S X 16" Jointer/Planer w/ Xylent Head (3PH)

Price:

$19,595 (USD)

Surfacing-thicknessing machine, professional, massive and compact, for a high-flexible production...

MiniMax FS41 Elite-S X 16" Jointer/Planer w/ Xylent Head (1PH)

Price:

$20,195 (USD)

Surfacing-thicknessing machine, professional, massive and compact, for a high-flexible production...

MiniMax CU300C 8.5' Combination Machine w/ 12'' Tersa Head

Price:

$13,985 (USD)

Universal combined machine with all minimax quality, at the most affordable price, ideal for dema...

MiniMax CU 300C 5.5' Combination Machine w/ 12'' Tersa Head

Price:

$12,985 (USD)

Universal combined machine with all minimax quality, at the most affordable price, ideal for dema...

MiniMax lab300p 5.5' Combination Machine w/ 12'' Tersa Head

Price:

$9,985 (USD)

Universal combined machine with all minimax quality, at the most affordable price, ideal for dema...

MiniMax CU 410E 8.5' Combination Machine w/ 16'' Tersa Head

Price:

$19,985 (USD)

Universal combined machine with all minimax quality, at the most affordable price, ideal for dema...

MiniMax CU 410ES 10.5' Combination Machine w/14'' Main Blade, 16'' Tersa Head

Price:

$27,985 (USD)

**Custom Order** Sales Price $26,000-$36,000 Universal combined machine with all minimax quality,...

MiniMax Startech 27- 3 Phase 27 Hole In-Line Boring Machine

Price:

$9,995 (USD)

Ideal for boring operations on panel. New models with 27 and 21 spindles. Rich basic equipment: i...

MiniMax AD 21- Single Phase 21 Hole Construction In-Line Boring Machine

Price:

$7,695 (USD)

Single head multiple boring machine with 21 spindles ideal for craftsmen and professional worksho...

SCM Group Class SI 400EP- BO- 3 Phase 10.5’ Programable Sliding Table Saw

Price:

$66,795 (USD)

Superior technology combined with an ease of use. Advantages Saw unit: a perfect cut. Maximum tor...

SCM Group Class SI X 3-Phase 10.5’ Programmable Sliding Table Saw

Price:

$52,895 (USD)

The advantages of an exclusive choice. Advantages Double blade tilting: maximum height without co...

SCM Group Class SI 350 - 3 Phase 10.5’ Sliding Table Saw

Price:

$19,595 (USD)

High construction quality for reliability and safe performance. Advantages Saw unit: a perfect cu...

SCM Group Nova SI 400EP - 3 Phase 10.5’ Programable Sliding Table Saw

Price:

$24,395 (USD)

Superior technology combined with an ease of use. Advantages Saw unit: a perfect cut. Maximum tor...

SCM Group NOVA SI 300S- 3Ph 5.5’ Manual Short Stroke Sliding Table Saw

Price:

$12,895 (USD)

Guaranteed quality at your fingertips Essential configuration with complete equipment to carry ou...

SCM Group CLASS TF 130PS Fixed Spindle Shaper

Price:

$15,585 (USD)

The "flexible" par excellence. Designed to manage tenoning and moulding operations very easily. A...

SCM Group CLASS TF 130 Fixed Spindle Shaper

Price:

$12,985 (USD)

The best solution for every application. Essential and professional the manual version. Technolog...

SCM Group NOVA TF 110 Fixed Spindle Shaper

Price:

$9,985 (USD)

Guaranteed quality at your finger tips. Easy-to-use, productivity and efficency, flexibility. Adv...

SCM Group TW 45C Fixed Spindle Shaper

Price:

$5,985 (USD)

The spindle moulder, with sliding table and fixed spindle, versatile and easy to use, ideal for D...

SCM Group Class SI 400 EP - 3 Phase 10.5’ Sliding Table Saw

Price:

$34,895 (USD)

Superior technology combined with an ease of use. Main functions: Connectivity among machines bel...

SCM Group Programmable Planer with Tersa Head L'Invincibile S7

Price:

$25,975 (USD)

SCM Group Programmable Planer with Tersa Head L'Invincibile S7 Standard Features 24" Helicoidal P...

SCM Group Nova S520 Planer w/Tersa

Price:

$13,975 (USD)

Guaranteed quality at your finger tips. Easy and precise, practical design, a wider range of appl...

SCM Group Nova S520 Planer w/ Xylent

Price:

$14,575 (USD)

Guaranteed quality at your finger tips. Easy and precise, practical design, a wider range of appl...

SCM Group Class S630 Planer w/ Tersa

Price:

$21,975 (USD)

The best solution for every application. Easy and precise, practical design, a wider range of app...

SCM Group Class S630 Planer w/ Xylent

Price:

$22,975 (USD)

The best solution for every application. Easy and precise, practical design, a wider range of app...

SCM Group 20" L'Invincibile Long Bed Jointer with Xylent Head F7 X

Price:

$20,575 (USD)

SCM Group 20" L'Invincibile Long Bed Jointer with Xylent Head F7 X Description Programmable 20” l...

SCM Group Nova F520 Jointer w/ Xylent

Price:

$13,275 (USD)

Guaranteed quality at your finger tips. Perfect surfaces, practical and safe, ergonomics. Advanta...

SCM Group Nova F520 Jointer w/ Tersa

Price:

$12,675 (USD)

Guaranteed quality at your finger tips. Perfect surfaces, practical and safe, ergonomics. Advanta...

SCM Group Nova F410 Jointer w/ Tersa

Price:

$10,975 (USD)

Guaranteed quality at your finger tips. Perfect surfaces, practical and safe, ergonomics. Advanta...

SCM Group Nova F410 Jointer w/ Xylent

Price:

$11,575 (USD)

Guaranteed quality at your finger tips. Perfect surfaces, practical and safe, ergonomics. Advanta...

SCM Minimax fs 30c x Jointer/Planer w/ Xylent Head

Price:

$5,995 (USD)

Massive, high-precision, professional band saws for serious woodworkers and production shops. The...

SCM E 20

Price:

$10,865 (USD)

Edge banding with hot melt glueon edges in rolls and strips on shaped panels, simply essential an...

SCM Me 25- 3 PH

Price:

$16,895 (USD)

Automatic edge bander with glue pot to edge band, with great flexibility, with melaminic edges, P...

SCM T 20

Price:

$8,985 (USD)

Trimming of shaped panels and with tilted edge.

Simply intelligent and versatile. Designed with ...

SCM Me 20

Price:

$10,985 (USD)

Technological solution, for professional craftsmen and joineries, to edge band with an amazing ea...

SCM Me 25- 1 PH

Price:

$17,595 (USD)

Automatic edge bander with glue pot to edge band, with great flexibility, with melaminic edges, P...

SCM Me 28et

Price:

$19,985 (USD)

Automatic edge bander with glue pot and pre-milling unit to edge band, with great flexibility, wi...

SCM OMAL Jolly Colla

Price:

$4,420 (USD)

The Jolly Colla is an automatic precision metering glue gun. Equipped with a multifunctional glue...

SCM Startech CN K Compact CNC Machine

Price:

$14,950 (USD)

(the machine stand in the picture is optional) Compact 3-axis machining centre ideal for all type...

SCM Startech CN V

Price:

$37,985 (USD)

startech cn v is the new CNC drilling machine with fixed work table and mobile workpiece. Vertica...

SCM Startech CN Plus

Price:

$63,985 (USD)

startech cn plus has been designed for the small-medium woodworking workshops but also for larger...

Mikron Multi-Moulder Model# M645

Price:

$27,980 (USD)

The MIKRON M645 Multi-Moulder is a versatile moulding machine, capable of handling many different...

Mikron Multi-Moulder with Router Model# M652R

Price:

$31,980 (USD)

A New Generation of Moulder... The First-Ever Horizontal Spindle System with Vertical Router Syst...

20'' Delta Bandsaw

Price:

The 20'' Delta Bandsaw is a refurbished piece of industrial equipment ideal for those needing pre...

Rockwell/ Invicta 16''Jointer

Price:

$6,000 (USD)

New Wire/ New Switches

Cleaned & Painted, 4 knife cutterhead

102'' Bed

The Invicta RJ-42 Joint...

SCM OMAL 1300 Cube

Price:

The HBD Cube is equipped with 3 Numerical Control axes, 3 vertical and 3 horizontal drilling unit...

SCM OMAL HG2

Price:

The HG2 is an Automatic Drilling and Inserting machine for hinges. The machine has a working fiel...

SCM OMAL HBD 1300 1H

Price:

The HBD 1300 1H is an Open Frame CNC machine to drill, glue and insert dowels with a 1300mm (51”)...

SCM OMAL Velox 1300

Price:

The OMAL Velox 1300 is a Horizontal Bore, Glue and Dowel and numerically controlled machines to d...

SCM Hypsos

Price:

Hypsos is the universal 5-axis machining center with integrated cabin, designed to process comple...

SCM Morbidelli m100/200

Price:

This highly modular machining center provides answers to all the problems associated with woodwor...

SCM Morbidelli m220

Price:

The machining center with double drilling head reduces drilling cycles by 70%, compared to other ...

SCM Accord 500

Price:

accord 500 is the machining center that combines compactness, ease of use and high technology bot...

SCM Accord 600

Price:

accord 600 represents the best design solution that does not compromise on performance when machi...

SCM Accord 30 fx

Price:

Machining center for the production of windows, doors, stairs, solid wood parts and for all those...

SCM Accord 40 fx

Price:

CNC machining center with mobile gantry structure for the production of windows, doors, stairs, s...

SCM Accord 42 fx

Price:

CNC machining center with mobile gantry structure equipped with a machining head consisting of tw...

SCM Accord 50 fx

Price:

5-axis CNC machining center with mobile gantry structure, designed for manufacturing complex-shap...

SCM Accord wd

Price:

Flexible work cell for the production of window and door frames, fitted with automatic loading an...

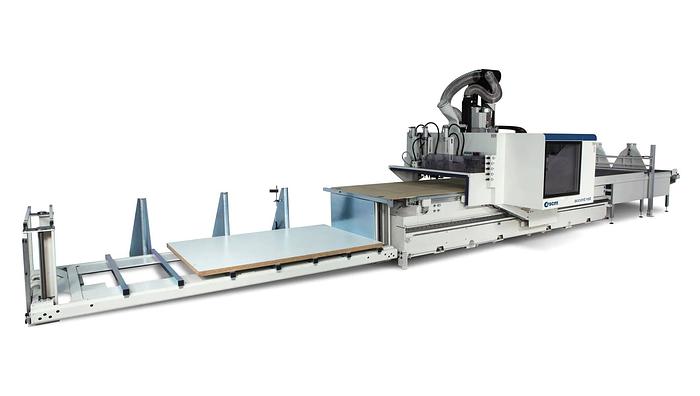

SCM Morbidelli x50

Price:

morbidelli x50 is an entry level CNC Nesting Machining Centre with wide equipment of routing and ...

SCM Morbidelli x100

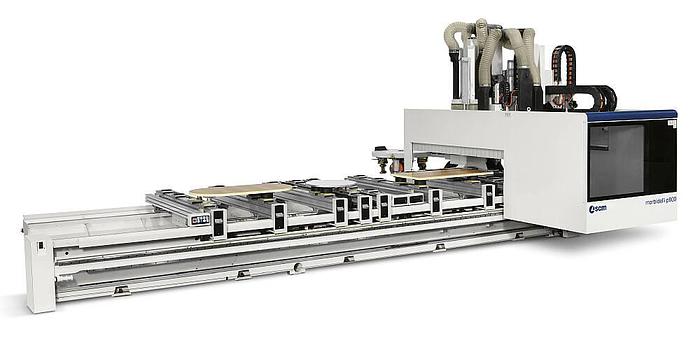

Price:

morbidelli x100 belongs to the new generation of Nesting CNC machining centres that meets the nee...

SCM Morbidelli n

Price:

Machining center designed and engineered for woodworking.

Thanks to the unique design and PRO-SP...

SCM Accord nst

Price:

A complete range of CNC machining centers integrated with automatic loading and unloading system ...

SCM Ergon nt

Price:

Cnc machining center with parallel heads designed for a wide range of applications, from panels i...

SCM Morbidelli m220f

Price:

The machining center with double drilling head reduces drilling cycles by 70%, compared to other ...

SCM Morbidelli m600/800f

Price:

Modular machining centers equipped with multi-function aluminium work table, able to guarantee hi...

SCM Accord 25 fxm

Price:

CNC machining center for highly flexible productions requiring superior precision and finish qual...

SCM Accord 30 fxm

Price:

Machining center equipped with the high-performance SCM multifunction worktable in aluminum, for ...

SCM Accord 40 fxm

Price:

CNC machining center with mobile gantry structure, for production of high flexibility and regardl...

SCM Accord 42 fxm

Price:

CNC machining centre with mobile gantry structure and fixed worktable designed for process solid ...

SCM Accord 50 fxm

Price:

5-axis CNC machining center with mobile gantry structure, designed for manufacturing complex-shap...

SCM Return Conveyor

Price:

SCM is pleased to introduce a standard ERC series conveyor to be paired with all edgebander model...

SCM Olimpic k 230 evo

Price:

Easy to use and equipped with everything you need for the complete edge banding of panels, olimpi...

SCM Olimpic k 360

Price:

Versatility and high machining quality with the SCM olimpic k 360, the machine with the aim to be...

SCM Olimpic 500

Price:

Olimpic 500 is a complete and versatile edgebander for SME's able to perform different machining ...

SCM Olimpic k 560

Price:

High performance and versatility: olimpic k 560 is designed for companies requiring to process ma...

SCM Stefani kd

Price:

Continuous and versatile solutions for quality machining are the distinctive features of stefani ...

SCM Stefani md

Price:

Perfect joint line and versatility of use with the new SGP glue pot (Smart Glue Pot) and the pre-...

SCM Stefani X

Price:

Industrial edge bander designed to offer the highest quality of processing on any type of panel a...

SCM Stefani S

Price:

stefani s is the single-sided edgebanding machine designed for medium-and large-scale firms and l...

SCM Stefani One

Price:

stefani one is a High End single-sided edgebander designed for large industry and for extra inten...

SCM Stefani psf

Price:

stefani psf is the industrial edgebander dedicated to post-forming or direct postforming process ...

SCM morbidelli p800

Price:

morbidelli p800 is a machining center for drilling, routing and edge treatment for the furniture ...

COIMA FI 10000

Price:

Reliable, powerful, silent…and easy to use.

The FI Series compact enclosed dust collectors are s...

COIMA FI 6000

Price:

Reliable, powerful, silent…and easy to use.

The FI Series compact enclosed dust collectors are s...

COIMA FI 4000

Price:

Reliable, powerful, silent…and easy to use.

The FI Series compact enclosed dust collectors are s...

COIMA F SERIES

Price:

The F-Series Compact Enclosed Dust Collector are designed for efficient filtration in smaller spa...

COIMA FC SERIES

Price:

The FC-Series Compact Enclosed Dust Collector are designed for efficient filtration in smaller sp...

COIMA FB SERIES

Price:

The FB-Series Compact Enclosed Dust Collector are designed for efficient filtration in smaller sp...

SCM Morbidelli m600/m800

Price:

Modular machining centres equipped with multi-function aluminium work table, able to guarantee hi...

SCM Morbidelli m100/200f

Price:

This highly modular machining centre provides answers to all the problems associated with woodwor...

SCM Morbidelli x200/x400

Price:

The new generation of Nesting CNC machining centres meets the needs of a market increasingly orie...

SCM Morbidelli m90

Price:

The new machining center with 3-4 axes technology shares the technological know-how of the "morbi...

SCM Morbidelli n

Price:

Thanks to the unique design and PRO-SPACE safety systems directly integrated onto the machine, a ...

CAP SERIES

Price:

The CAP Series Dust Capture Booth is made of galvanized steel for the capture and extraction of d...

FB SERIES

Price:

The FB-Series Compact Enclosed Dust Collector are designed for efficient filtration in smaller sp...

FC SERIES

Price:

The FC-Series Compact Enclosed Dust Collector are designed for efficient filtration in smaller sp...

F SERIES

Price:

The F-Series Compact Enclosed Dust Collector are designed for efficient filtration in smaller spa...

V 235 NC

Price:

Fully Automatic CNC Mitering System with fixed blade angle. 14" saw blades. Complete with hopper ...

V 2013 NC

Price:

Fully Automatic CNC Mitering System with adjustable blade angle. 12" saw blades. Complete with ho...

V 235

Price:

Double Mitre Saw for "V" cutting and Picture Frames. Two 14" saw blades, 3 1/2" width capacity. L...

TRF 527

Price:

8.5" Double Mitre Chop Saw 1.5HP Motors Width Cutting Capacity 2" Thickness Capacity 1 1/2" Lengt...

TRF 527 VIS

Price:

8.5" Double Mitre Chop Saw 1.5HP Motors Width Cutting Capacity 2" Thickness Capacity 1 1/2" Lengt...

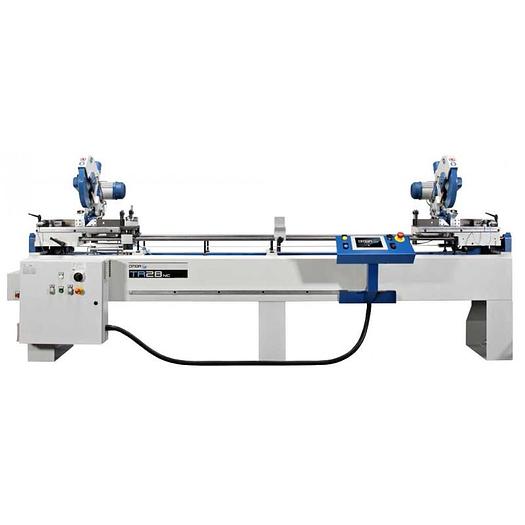

TR 2A NC

Price:

12" Double Mitre Chop Saw 2.2HP Motors Width Cutting Capacity 6" Thickness Capacity 3 1/2" Length...

TRF 527 NC

Price:

8.5" Double Mitre Chop Saw 1.5HP Motors Width Cutting Capacity 2" Thickness Capacity 1 1/2" Lengt...

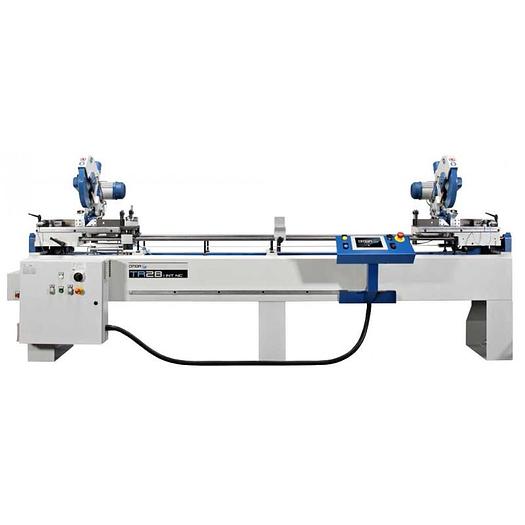

TR 2A

Price:

12" Double Mitre Chop Saw 2.2HP Motors Width Cutting Capacity 6" Thickness Capacity 3 1/2" Length...

TR 2A VIS

Price:

12" Double Mitre Chop Saw 2.2HP Motors Width Cutting Capacity 6" Thickness Capacity 3 1/2" Length...

TR 2B NC

Price:

14" Double Mitre Chop Saw 3HP Motors Width Cutting Capacity 6 5/8" Thickness Capacity 4 1/8" Leng...

TR 2B I INT NC

Price:

14" COMPOUND Double Mitre Chop Saw 4HP Motors Width Cutting Capacity 6 1/2" Thickness Capacity 4 ...

TR 2B VIS

Price:

14" Double Mitre Chop Saw 3HP Motors Width Cutting Capacity 6 5/8" Thickness Capacity 4 1/8" Leng...

TR 2B I INT VIS

Price:

14" COMPOUND Double Mitre Chop Saw 4HP Motors Width Cutting Capacity 7" Thickness Capacity 4 1/8"...

TR 2B

Price:

14" Double Mitre Chop Saw 3HP Motors Width Cutting Capacity 6 5/8" Thickness Capacity 4 1/8" Leng...

RAS 900

Price:

18" Radial Arm Saw 7.5HP Motor, 32 1/4" Cross Cut Capacity, 45" Rip Capacity. Cast Iron Arm. Thes...

OMGA Stop 6 - LH

Price:

Programmable Stop/Positioner System with 6'6" of useable traverse. Left Hand. The OMGA StopTM - 6...

OMGA Stop 13 - LH

Price:

Programmable Stop/Positioner System with 13'1" of useable traverse. Left Hand. The OMGA StopTM - ...

OMGA Stop 10 - LH

Price:

Programmable Stop/Positioner System with 10' of useable traverse. Left Hand. The OMGA StopTM - 10...

OMGA Stop 16 - LH

Price:

Programmable Stop/Positioner System with 16'4" of useable traverse, w/precision linear encoder sy...

RAS 1250

Price:

20" Radial Arm Saw 7.5HP Motor, 44" Cross Cut Capacity, 56" Rip Capacity. Cast Iron Arm. These pr...

OMGA Stop 22 - LH

Price:

Programmable Stop/Positioner System with 22' of useable traverse, w/precision linear encoder syst...

OMGA Stop 6 - RH

Price:

Programmable Stop/Positioner System with 6'6" of useable traverse. Right Hand. The OMGA StopTM - ...

OMGA Stop 16 - RH

Price:

Programmable Stop/Positioner System with 16'4" of useable traverse, w/precision linear encoder sy...

OMGA Stop 10 - RH

Price:

Programmable Stop/Positioner System with 10' of useable traverse. Right Hand. The OMGA StopTM - 1...

OMGA Stop 13 - RH

Price:

Programmable Stop/Positioner System with 13'1" of useable traverse. Right Hand. The OMGA StopTM -...

OMGA Stop 22 - RH

Price:

Programmable Stop/Positioner System with 22' of useable traverse, w/precision linear encoder syst...

T 521 SNC

Price:

Automatic push fed saw for sequenced cutting with 18" saw blade. Last Generation automatic progra...

OPTIMA 120 SNC

Price:

Automatic push fed saw for optimized and pack cutting. The OPTIMA 120 is a Push-Feed Optimizing a...

OPTIMA 60 SNC

Price:

Automatic push fed saw for optimized and pack cutting. The OPTIMA 60 is a Push-Feed Optimizing an...

T 521 ST

Price:

18" Cut-Off Saw 6HP Motor 12 5/8" Cross Cut Capacity Pneumatic adjustable speed pop-up chop saw, ...

OPTIMA 60

Price:

Automatic push fed saw for optimized cutting and defect removal The OPTIMA 60 is a Push-Feed Opti...

OPTIMA 240

Price:

High speed automatic push fed saw for optimized cutting and defect removal. The OPTIMA 240 is a P...

OPTIMA 120 Elite

Price:

High speed automatic push fed saw for optimized cutting and defect removal. OPTIMA 120 Elite is a...

OPTIMA 120

Price:

Automatic push fed saw for optimized cutting and defect removal The OPTIMA 120 is a Push-Feed Opt...

T 2020 NC

Price:

High Speed Automatic Cut-off Saw programmable for optimized cutting of wood stock and defect remo...

T 2030 NC

Price:

Last generation, 800 FPM automatic programmable cut-off saw for optimized cutting of wood stock a...

LEADERMAC | Super Thundermac Moulder SeriesLEADERMAC | Super Thundermac Moulder SeriesCookie and Privacy Settings

Price:

Why Leadermac Super Thundermac Moulder Series? Heavily built fabricated steel frame ensures the p...

CANTEK | JF330A PROFILE GRINDERCANTEK | JF330A PROFILE GRINDERCookie and Privacy Settings

Price:

Why Cantek JF330A Profile Grinder? Powerful 3 HP grinding motor, allowing deep aggressive grindin...

LEADERMAC | SPEEDMAC MOULDER SERIESLEADERMAC | SPEEDMAC MOULDER SERIESCookie and Privacy Settings

Price:

Why Leadermac Speedmac Moulder Series? Heavily built cast iron frame, or fabricated steel frame, ...

LEADERMAC | Thundermac Moulder SeriesLEADERMAC | Thundermac Moulder SeriesCookie and Privacy Settings

Price:

Why Leadermac Thundermac Moulder Series? Heavily built cast iron or fabricated steel frame ensure...

LEADERMAC | Platinum Moulder SeriesLEADERMAC | Platinum Moulder SeriesCookie and Privacy Settings

Price:

Why Leadermac Platinum Moulder Series? A full touch screen control system keeping all history fil...

LEADERMAC | Hypermac Moulder SeriesLEADERMAC | Hypermac Moulder SeriesCookie and Privacy Settings

Price:

Why Leadermac Hypermac Moulder Series? Industrial moulder design with a solid cast iron frame pro...

LEADERMAC | Planermac Moulder SeriesLEADERMAC | Planermac Moulder SeriesCookie and Privacy Settings

Price:

Why Leadermac Planermac Moulder Series? Heavily built fabricated steel frame ensures the producti...

DM200RHC

Price:

14" Double end trim mitre saw TBA Specifications Double end trim mitre saw 2 H.P. 3phase Magnetic...

LEADERMAC | Compact Moulder SeriesLEADERMAC | Compact Moulder SeriesCookie and Privacy Settings

Price:

Why Leadermac Compact Moulder Series? Industrial moulder design with a solid cast iron frame prod...

LEADERMAC | Smartmac Moulder SeriesLEADERMAC | Smartmac Moulder SeriesCookie and Privacy Settings

Price:

Why Leadermac Smartmac Moulder Series? Industrial moulder design with a solid cast iron frame pro...

UCS222-A

Price:

22" Blade capacity semi automatic cut-off saw The CTD up-cut saws are engineered for accurate, fa...

DM400

Price:

16" Double end trim mitre saw The DM400 uses two standard 400 Series saw heads. See 400 Series fe...

UCS218-A

Price:

18" Blade capacity semi automatic cut-off saw These up-cut saws are engineered for accurate, fast...

DM200R

Price:

12" Double end trim mitre saw TBA Specifications Double end trim mitre saw 2 H.P. 3phase Magnetic...

CDM300R

Price:

12" Compound double end trim mitre saw The CTD Model CDM300R is our most versatile 12" Double End...

CDM60

Price:

16" Compound double end trim mitre saw The CTD Model CDM60 offers a maximum of flexibility and cu...

CM60

Price:

16" Mitre & Compound cut-off saw These saws cut your costs, are accurate, rugged, and give long l...

N90S

Price:

18" Special staggered blade toe notching saw The Model N90 has been designed for a variety of hea...

N90

Price:

16" Vertical frame and notching saw The Model N90 has been designed for a variety of heavy duty c...

CS-14

Price:

14" Mitre cold saw CTD Machines new CS-14 is a 14” cold saw with a dual speed motor winding. This...

D45AX 14

Price:

CTD Model D45AX14 Frame & Notching Saw The CTD 400 Series Cut Off Saws are designed for heavy dut...

D45AX

Price:

12" Fixed head double mitre saw The D45 is popular world wide because of its unique features, low...

CS-12

Price:

12" Mitre cold saw CTD Machines new CS-12AF is a 12” cold saw with a dual speed motor winding. Th...

F255

Price:

12" Straight cut-off saw The Model F255R uses the same sawhead as the M25R, but cuts 90° only. Sp...

M25RHC

Price:

14" Mitre cut-off saw This rugged, accurate heavy duty industrial indexing mitre cut-off saw uses...

Jobsite Saw Pro JSS™

Price:

$1,599 (USD)

Class-Leading Table Depth: 24 5/8” table depth allows a larger surface to make safe and accurate ...

M25R

Price:

12" Mitre cut-off saw This rugged, accurate heavy duty industrial indexing mitre cut-off saw uses...

UCS 222MQ

Price:

22" Blade capacity semi automatic Miter cut-off saw, Manual, Quill controlled, or Digital option ...

UCS 222M

Price:

22" Blade capacity semi automatic Miter cut-off saw, Manual, Quill controlled, or Digital option ...

UCS 218

Price:

18" Blade capacity semi automatic cut-off saw These up-cut saws are engineered for accurate, fast...

UCS 222

Price:

22" Blade capacity semi automatic cut-off saw The CTD up-cut saws are engineered for accurate, fa...

NT-UCS24R-AS UP CUT SAW RIGHT HAND ALUMINUM SERIES

Price:

NT-UCS24R-AS UP CUT SAW RIGHT HAND ALUMINUM SERIES The NT UCS24R-AS Up Cut Saw is a step up in ca...

NT-UCS24L-AS UP CUT SAW LEFT HAND ALUMINUM SERIES

Price:

NT-UCS24L-AS UP CUT SAW LEFT HAND ALUMINUM SERIES The NT UCS24L-AS Up Cut Saw is a step up in cap...

NT-UCS30L UP CUT SAW LEFT HAND

Price:

NT-CS30L UP CUT SAW LEFT HAND NT-CS30L UP CUT SAW LEFT HAND Main motor hp: 15 HP | Voltage, frequency: 230/4...

NT-880S-HSK SHAPER WITH SLIDE

Price:

Northtech shapers are built for industrial use. The NT-880SHSK is our 15HP quick tool change shap...

NT-UCS20R UP CUT SAW RIGHT HAND

Price:

The NT UCS20R Up Cut Saw is in the middle of the family of Northtech Up Cut Saws. Upcut Saws hous...

NT-880-HSK SHAPER

Price:

Northtech shapers are built for industrial use. The NT-8800HSK is our 10HP quick tool change shap...

NT-UCS18R-AS UP CUT SAW RIGHT HAND ALUMINUM SERIES

Price:

The NT UCS18R-AS Up Cut Saw is a popular saw for cutting aluminum. Upcut Saws house the blade ins...

NT-UCS20L UP CUT SAW LEFT HAND

Price:

The NT UCS20L Up Cut Saw is in the middle of the family of Northtech Up Cut Saws. Upcut Saws hous...

NT-800T SHAPER WITH TILTING SPINDLE

Price:

The NT 800T is the 800 series shaper equipped with a tilting spindle. The 800 series features a l...

NT-UCS18R UP CUT SAW RIGHT HAND

Price:

The NT UCS18R Up Cut Saw is the most popular model in the Northtech Up Cut Saw family. Up Cut Saw...

NT-UCS18L UP CUT SAW LEFT HAND

Price:

The NT UCS18L Up Cut Saw is the most popular model in the Northtech Up Cut Saw family. Upcut Saws...

NT-UCS18L-AS UP CUT LEFT HAND SAW ALUMINUM SERIES

Price:

The NT UCS18L-AS Up Cut Saw is a popular saw for cutting aluminum. Up cut Saws house the blade in...

NT-900C WIDE BELT SANDER

Price:

The NT-900C single combination head wide belt sander has a 36″ working width and comes standard w...

NT-UCS14R UP CUT SAW RIGHT HAND

Price:

The NT UCS14R Up Cut Saw is the baby of the Northtech Up Cut Saw family. Upcut Saws house the bla...

NT-8-900RC WIDE BELT SANDER

Price:

NT-8-900RC WIDE BELT SANDER The NT 8-900RC roller combination head wide belt sander has a 36″ wor...

NT-8-600RC WIDE BELT SANDER 24″

Price:

NT-600RC WIDE BELT SANDER 24″ 25X75″ SANDING BELT NT-600RC WIDE BELT SANDER 24″ 25X75″ SANDING BELT Machine ...

NT-9-1100RC WIDE BELT SANDER

Price:

NT-9-1100RC WIDE BELT SANDER NT-9-1100RC WIDE BELT SANDER Machine hp: 37 HP | Voltage, frequency: 230/460 Vo...

NT-770S-HSK SHAPER WITH SLIDE

Price:

Northtech shapers are built for industrial use. The NT-770HSK is our 10HP quick tool change shape...

NT-770-HSK SHAPER

Price:

Northtech shapers are built for industrial use. The NT-770HSK is our 10HP quick tool change shape...

NT-735TS SHAPER WITH TILTING SPINDLE, SLIDING TABLE

Price:

The NT 735TS is the 735 shaper equipped with a sliding table and tilting spindle. The 735 series ...

NT-735T SHAPER WITH TILTING SPINDLE

Price:

The NT 735T is the 735 shaper equipped with a tilting spindle. The 735 series features a large st...

NT-UCS14L UP CUT SAW LEFT HAND

Price:

The NT UCS14L Up Cut Saw is the baby of the Northtech Up Cut Saw family. Upcut Saws house the bla...

NT-CS36L UP CUT SAW LEFT HAND

Price:

The NT CS36L Up Cut Saw is the largest cross cut saw we offer. Left handed Up Cut Saws have the b...

NT-CS36R UP CUT SAW RIGHT HAND

Price:

The NT CS36R Up Cut Saw is the largest cross cut saw we offer. Upcut Saws house the blade inside ...

NT-HRR3 HORIZONTAL REMAN RESAW

Price:

The NT-HRR3 is a unique horizontal resaw with a vertical trough feeding system that is used to si...

NT-CS30R UP CUT SAW RIGHT HAND

Price:

The NT CS30R Up Cut Saw is the second largest cross cut saw we offer. Upcut Saws house the blade ...

NT-8-1300RC WIDE BELT SANDER

Price:

NT-8-1300RC WIDE BELT SANDER The NT-8-1300RC is two head wide belt sander that has a 51″ working ...

NT-600C WIDE BELT SANDER

Price:

The NT-600C single combination head wide belt sander has a 24″ working width and comes standard w...

NT-8-1100RC WIDE BELT SANDER

Price:

NT-8-1100RC WIDE BELT SANDER The NT-8-1100RC is two head wide belt sander that has a 43″ working ...

NT-1300C WIDE BELT SANDER

Price:

NT-1300C WIDE BELT SANDER The NT-1300C single combination head wide belt sander has a 51″ working...

NT-ES972DE EDGE SANDER DOUBLE TABLE

Price:

Northtech offers a large family of industrial grade edge sanders. The NT-ES9672DE offers our long...

NT-ES960SE EDGE SANDER SINGLE TABLE BELT 9″ X 158″, PLATEN 9.5″ X 60″

Price:

Northtech offers a large family of industrial grade edge sanders. The NT-ES960SE is a popular siz...

NT-735S SHAPER WITH SLIDING TABLE

Price:

The NT 735S is the 735 shaper equipped with a sliding table. The 735 series features a large stab...

NT-ES960DE EDGE SANDER DOUBLE TABLE

Price:

Northtech offers a large family of industrial grade edge sanders. The NT-ES960DE is a popular siz...

NT-735M SHAPER

Price:

The NT 735 shaper is one of the best built shapers available. Matching the powerful 10hp intercha...

NT-ES948SE EDGE SANDER SINGLE TABLE

Price:

NT-ES948SE EDGE SANDER SINGLE TABLE Northtech offers a large family of industrial grade edge sand...

NT-735LT SHAPER LONG BED WITH TILTING SPINDLE

Price:

NT-735LT SHAPER WITH LONG BED TILTING SPINDLE The NT 735LT shaper is our heavy duty 735 series ma...

NT-625TS SHAPER WITH TILTING SPINDLE, SLIDING TABLE

Price:

NT-625TS SHAPER WITH TILTING SPINDLE, SLIDING TABLE The NT 625TS is the 625 shaper equipped with ...

NT-S5230 MOULDER 5 HEAD

Price:

NT-S5230 MOULDER 5 HEAD The NT S5230 is a compact heavy duty 5 head moulder with large moulder ca...

NT-TB5XL TRANSFER BLOWER

Price:

The NT TB5XL is our 5HP belt driven transfer blower with a fabricated steel housing. The belt dri...

NT-S4230-1 MOULDER 4 HEAD

Price:

NT-S4230-1 MOULDER 4 HEAD The NT S4230-1 is a compact heavy duty 4 head moulder with large moulde...

NT-SFRS29 STOCK FEEDER RESAW

Price:

NT-SFRS29 STOCK FEEDER RESAW NT-SFRS29 STOCK FEEDER RESAW Main motor hp: 1/2 HP | Direct drive (motor): Yes

NT-TB5 TRANSFER BLOWER

Price:

The NT TB5 is our 5HP direct drive transfer blower. The powerful direct drive design allows for a...

NT-DC7SS DUST COLLECTOR

Price:

NT-DC7SS DUST COLLECTOR SOFT SOUND WITH SHAKERS NT-DC7SS DUST COLLECTOR SOFT SOUND WITH SHAKERS Machine hp: ...

NT-CS30L UP CUT SAW LEFT HAND

Price:

The NT CS30L Up Cut Saw is the second largest cross cut saw we offer. Upcut Saws house the blade ...

NT-SFJ12 STOCK FEEDER JOINT 12″

Price:

Northtech Stock Feeders are some of the strongest and longest lasting feeders available. Stock fe...

NT-CS24RT UP CUT SAW ROTARY TABLE

Price:

NT-CS24RT UP CUT SAW ROTARY TABLE The NT-CS24RT Up Cut Saw is a powerful upcut with 24″ blade and...

NT-CS26RT UP CUT SAW ROTARY TABLE

Price:

The NT-CS26RT Up Cut Saw is a powerful upcut with 26″ blade and a rotary table allowing it to cut...

NT-CS26RT-AS UP CUT SAW ROTARY TABLE ALUMINUM SERIES

Price:

The NT-CS26RT-AS Up Cut Saw is a powerful upcut with 26″ blade and a rotary table allowing it to ...

NT-MRS700 GANG RIP SAW HEAVY DUTY DOUBLE ARBOR

Price:

The NT MRS700 is our double arbor Multiple Rip Saw with a maximum thickness cut of 8.5″ with dual...

NT-SRS12NS STRAIGHT LINE RIP SAW

Price:

Northtech Straight Line Rip Saws provide accurate straight cuts for glue ups and blank production...

NT-HBR300PBX HORIZONTAL BAND RESAW

Price:

NT-HBR300PBX HORIZONTAL BAND RESAW NT-HBR300PBX HORIZONTAL BAND RESAW Main motor hp: 30 HP | Voltage, freque...

NT-MRS340 GANG RIP SAW

Price:

The NT MRS340 Multiple Rip Saw features a cast iron frame that houses a variable speed dip chain ...

NT-MRS350 GANG RIP SAW

Price:

The NT MRS350 Multiple Rip Saw features a cast iron frame that houses a variable speed dip chain ...

NT-HBR250BS-2A HORIZONTAL BAND RESAW TWO HEAD

Price:

NT-HBR250BS-2A HORIZONTAL BAND RESAW TWO HEAD The Northtech HBR250BS-2A is a (2) headed resaw. Th...

NT-HBR24PB HORIZONTAL BAND RESAW WITH POWERED RETURN

Price:

NT-HBR24PB HORIZONTAL BAND RESAW WITH POWERED RETURN NT-HBR24PB HORIZONTAL BAND RESAW WITH POWERE...

NT-12-1300RRC WIDE BELT SANDER

Price:

NT-12-1300RRC WIDE BELT SANDER While Northtech Wide Belt Sanders have been trusted for decades in...

NT-HBR24PBXT HORIZONTAL BAND RESAW WITH POWERED RETURN WITH TILT

Price:

The Northtech HBR24PBXT is our 24″ horizontal resaw. This machine has a 24″x8″ cut capacity, digi...

NT-12-1300R WIDE BELT SANDER

Price:

NT-12-1300R WIDE BELT SANDER While Northtech Wide Belt Sanders have been trusted for decades in w...

NT-12-1100RC WIDE BELT SANDER

Price:

NT-12-1100RC WIDE BELT SANDER While Northtech Wide Belt Sanders have been trusted for decades in ...

NT-12-1100RP WIDE BELT SANDER

Price:

NT-12-1100RP WIDE BELT SANDER NT-12-1100RP WIDE BELT SANDER Voltage, frequency: 230/460 Volt 60 Hz | Phase: ...

NT-ES948DE EDGE SANDER SINGLE TABLE

Price:

NT-ES948DE EDGE SANDER SINGLE TABLE Northtech offers a large family of industrial grade edge sand...

NT-ES648DE EDGE SANDER DOUBLE TABLE

Price:

Northtech offers a large family of industrial grade edge sanders. The NT-ES648DE is a compact edg...

NT-ES636SE EDGE SANDER SINGLE TABLE

Price:

NT-ES636SE EDGE SANDER SINGLE TABLE Northtech edge sanders are built for the industrial use. The ...

NT-ES636DE EDGE SANDER DOUBLE TABLE

Price:

Northtech edge sanders are built for the industrial use. The NT-ES636DE is our most compact edge ...

NT-iGlue450 Dovetail Gluer

Price:

NT-iGlue450 Dovetail Gluer Automatic 18″ The Northtech iGlue is the revolutionary new gluer that ...

NT-iDovetail30 DOVETAILER

Price:

NT-iDovetail30 DOVETAILER Northtech’s iDovetail30 is our largest award winning single spindle 3-a...

NT-iDovetail24 DOVETAILER

Price:

NT-iDovetail24 DOVETAILER Northtech’s iDovetail24 is our award winning single spindle 3-axis CNC ...

NT-625T SHAPER WITH TILTING SPINDLE

Price:

The NT 625T is the 625 shaper equipped with a tilting spindle. The 625 series features a large st...

NT-625M SHAPER

Price:

The 625M shaper is a powerful strong, heavy duty built shaper. The 625 series features a large st...

NT-625S SHAPER WITH SLIDING TABLE

Price:

The NT 625MS is the 625 shaper equipped with a sliding table. The 625 series features a large sta...

NT-525TS SHAPER WITH TILTING SPINDLE, SLIDING TABLE

Price:

The NT 525TS is the 525 shaper equipped with a sliding table and tilting spindle. The 525 series ...

NT-S4230 MOULDER 4 HEAD

Price:

NT-S4230 MOULDER 4 HEAD The NT S4230 is a compact heavy duty 4 head moulder with large moulder ca...

NT-RM80-2SS ROD MILLING DOUBLE HEAD

Price:

NT-RM80-2SS ROD MILLING DOUBLE HEAD The NT RM80-2SS rod milling machine is designed to take squar...

NT-N6230 MOULDER 6 HEAD

Price:

NT-N6230 MOULDER 6 HEAD The NT N6230 is quite possibly the best valued moulder available. The 6″ ...

NT-N4230 MOULDER 4 HEAD

Price:

NT-N4230 MOULDER 4 HEAD The NT N4230 is our standard 4 head N series machine. The 6″ x 9″ capacit...

NT-N6230-3 MOULDER 6 HEAD

Price:

NT-N6230-3 Moulder 6 Head The NT N6230 is quite possibly the best valued moulder available. The 6...

NT-TB25XL TRANSFER BLOWER

Price:

The NT TB25XL is our 25HP belt driven transfer blower with a fabricated steel housing. The belt d...

NT-TB20 TRANSFER BLOWER

Price:

The NT TB20 is our 20HP direct drive transfer blower. The powerful direct drive design allows for...

NT-TB25 TRANSFER BLOWER

Price:

The NT TB25 is our 25HP direct drive transfer blower. The powerful direct drive design allows for...

NT-TB2 TRANSFER BLOWER

Price:

The NT TB2 is our 2HP direct drive transfer blower. The powerful direct drive design allows for a...

NT-DC15SS DUST COLLECTOR

Price:

NT-DC15SS DUST COLLECTOR SOFT SOUND WITH SHAKERS NT-DC15SS DUST COLLECTOR SOFT SOUND WITH SHAKERS Machine hp...

NT-DC5SS DUST COLLECTOR

Price:

NT-DC5SS DUST COLLECTOR SOFT SOUND WITH SHAKERS NT-DC5SS DUST COLLECTOR SOFT SOUND WITH SHAKERS Machine hp: ...

LEADERMACLMC330SK Saw Kerf Marking Machine ImagesVideoMachine InformationCookie and Privacy Settings

Price:

LEADERMACLMC330SK Saw Kerf Marking Machine LMC330SK Saw Kerf Marking Machine Images The machine i...

NT-DC3075 DUST COLLECTOR

Price:

The NT DC3075 is a mobile dust collector with a triple top filter bag and triple bottom collectio...

NT-DC50 DUST COLLECTOR

Price:

The NT DC50 is a strong portable dust collector with a double top filter bag and double bottom co...

NT-820HC DOUBLE SURFACE PLANER

Price:

The NT 820HC is our 32″ width double surfacer with over 6″ thickness capability. Double surfacers...

NT-DC30 DUST COLLECTOR

Price:

NT-DC30 DUST COLLECTOR The NT DC30 is the smallest dust collector Northtech offers with a double ...

NT-760XL DOUBLE SURFACE PLANER

Price:

The NT 760XL is our 30″ chain drive double surfacer with 8″ thickness capability. Double surfacer...

NT-610XL DOUBLE SURFACE PLANER

Price:

The NT 610XL is our most popular chain drive double surfacer. Double surfacers, some times referr...

NT-610SS DOUBLE SURFACE PLANER

Price:

The NT 610SS is our most robust 24″ double surfacer with up to 75HP and feed speeds of 190fpm. Do...

NT-850HCVS SINGLE SURFACE PLANER

Price:

NT-850HCVS SINGLE SURFACE PLANER The NT 850-30 is our 30HP Single Surface Planer with 33.5″ worki...

NT-760HCVS SINGLE SURFACE PLANER

Price:

The NT760-25 is our 25HP Single Surface Planer with 30″ working width. This planer has a heavy du...

NT-660SHCVS SINGLE SURFACE PLANER

Price:

NT-660SHCVS SINGLE SURFACE PLANER NT-660SHCVS SINGLE SURFACE PLANER Top head hp: 20 HP | Voltage, frequency:...

LEADERMACProset Setworks Control ImagesMachine InformationCookie and Privacy Settings

Price:

LEADERMACProset Setworks Control Proset Setworks Control Images The PROSET system was designed us...

NT-24KHC3S SINGLE SURFACE PLANER

Price:

The NT 24K-10HC3S is our 24″ entry level planer. A classical but rugged and dependable design wit...

LEADERMACM307 Electronic Video Measuring System ImagesMachine InformationCookie and Privacy Settings

Price:

LEADERMACM307 Electronic Video Measuring System M307 Electronic Video Measuring System Images Lea...

LEADERMACEasy Set Controls ImagesMachine InformationCookie and Privacy Settings

Price:

LEADERMACEasy Set Controls Easy Set Controls Images Easyset Setworks Includes a Schneider 5.7” HM...

LEADERMAC523C Short Stock Moulder with Feedmac 08 Random Length Feeder Machine InformationCookie and Privacy Settings

Price:

LEADERMAC523C Short Stock Moulder with Feedmac 08 Random Length Feeder 523C Short Stock Moulder w...

LEADERMACSmartSet 100 Touch Screen Control System ImagesMachine InformationCookie and Privacy Settings

Price:

LEADERMACSmartSet 100 Touch Screen Control System SmartSet 100 Touch Screen Control System Images...

LEADERMACSmartmac with Auto Width Set Control System (Random Width Moulder) Machine InformationCookie and Privacy Settings

Price:

LEADERMACSmartmac with Auto Width Set Control System (Random Width Moulder) Smartmac with Auto Wi...

INNOVATOR CUTMATE 700C CROSS CUT VENEER CLIPPER

Price:

Northtech supports the Innovator and Savi Veneer lines. The Cutmate 700 is a crosscut bundle clip...

NT-TDH1015 TRAP DOOR HOPPER

Price:

NT-TDH1015 TRAP DOOR HOPPER 52″Lx70″Wx 33″H, 3 INLET PORTS, APPROX 2.57 YARDS WHEN FULL NT-TDH101...

NT-SF70 STOCK FEEDER 7 ROLLERS WITH UNIVERSAL STAND

Price:

Northtech Stock Feeders are some of the strongest and longest lasting feeders available. Stock fe...

NT-TDH57 TRAP DOOR HOPPER

Price:

NT-TDH57 TRAP DOOR HOPPER 52″Lx51.5″Wx 33″H, 2 INLET PORTS, APPROX 1.89 YARDS WHEN FULL NT-TDH57 ...

NT-SF40 STOCK FEEDER 4 ROLLERS WITH UNIVERSAL STAND

Price:

Northtech Stock Feeders are some of the strongest and longest lasting feeders available. Stock fe...

NT-040SF STOCK FEEDER W/ STAND 3 BELTS 8 SPEEDS

Price:

Northtech Stock Feeders are some of the strongest and longest lasting feeders available. Stock fe...